Demand Driven Manufacturing Transformations

High Impact Coaching & Strategies has decades of experience promoting Demand Driven strategies in our customers’ factories and across their global supply chains. We provide our customers with cutting-edge Demand Driven solutions focused on establishing the capabilities to create flow, compress lead times and reduce inventory, generating sustainable bottom-line benefits.

As a leading provider of Demand Flow Technology consulting, we help our clients achieve sustainable operational capabilities developing Demand Driven manufacturing solutions that create a competitive advantage in the marketplace. Our world-class service and thought leadership mixed with a blend of real-world experience and practical training technique,s will help you achieve your financial objectives.

We believe that improved product, material & information flow, with balance and increased predictability from your facility will enable a more agile (faster & more repeatable lead time) operation. Agile Demand Driven operations utilize less space, require less working capital, have lower operating costs and enable world-class customer service lead times; while being easier to manage. Discover Demand Driven manufacturing consulting solutions with foundations based on Demand Flow Technology driving significant sustainable performance improvements through lead time compression, improved productivity and cost reduction.

Creating a Demand Driven Manufacturing Facility

At High Impact, we understand the challenges faced on a daily basis by manufacturing companies as they attempt to meet customer requirements while coping with the strains of being part of a global supply chain network. We work with all sizes of companies to implement Demand Driven methodologies such as Demand Flow Technology to compress manufacturing lead times and create an unimpeded flow of product through a facility. At the same time, our transformational design process will improve productivity and reduce overall floor space within your manufacturing facility.

We have a proven history of delivering transformational business projects that will impact the business and turn your manufacturing facility into a strategic weapon unlocking significant sustainable benefits and a competitive advantage in the market-place. Transform your manufacturing operations to deliver improvements in working capital, operating cost and customer service levels through the deployment of High Impact’s best-in-class Demand Driven manufacturing methodologies.

Unlocking Your Manufacturing Capabilities

Through the deployment of our transformation programs, your business will benefit from:

Up to 70%

Up to 50%+

Up to 25%

Up to 100%

Up to 20%

Up to 20%

In the above, each section has a text block that has % text in white so not shown above and white on blue on the website.

Below is the copy not shown on the website with readable % text

Up to 70%

Up to 50%+

Up to 25%

Up to 100%

Up to 20%

Up to 20%

The Results

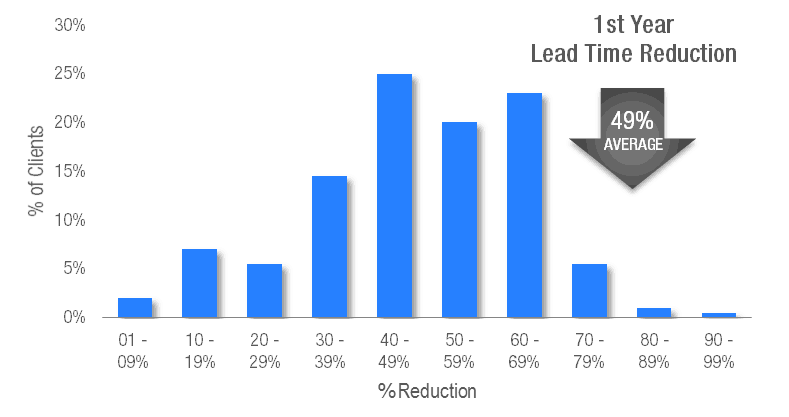

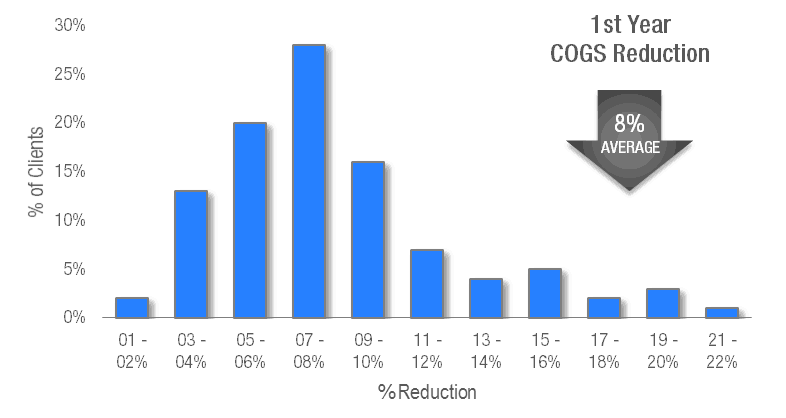

Significant sustainable performance improvements through lead time compression, improved productivity and cost reduction

Following successful DFT training, our leadership unanimously agreed to invite High Impact Coaching & Strategies to consult on a “refresh” of one of our assembly areas. Given the highly configurable nature of our products, we partnered on our highest revenue-generating assembly area, consisting of 5 production lines. This collaboration has proven to be exceptionally valuable. Sandy demonstrates meticulous attention to detail in gathering necessary data and collaborates closely with our diverse team members to define the information required for optimal production flow scenarios. He facilitates cross-functional engagement, guiding process, product, and material movement teams through each step and providing insightful answers to all inquiries. We are now approaching the final implementation phase of this initiative and anticipate achieving a return on investment within approximately three months. I offer my highest recommendation for Sandy Goodwin and High Impact Coaching & Strategies for any organization seeking expert guidance in flow evaluation and process improvement. Sandy’s professionalism, integrity, and strong ethical and collaborative approach have made him, and High Impact Coaching & Strategies, a valued partner, and we have greatly appreciated his contributions to our team.

Sandy Goodwin of High Impact Coaching & Strategies brought structure and measurable impact to our operations through the invaluable tools and processes they developed. We successfully designed and implemented a robust Sales & Operations Planning (S&OP) process, significantly enhancing our ability to balance demand and supply across the business. High Impact’s guidance in customer and product segmentation, along with product family definition and the implementation of a robust statistical forecasting model, greatly simplified and improved the accuracy of our demand planning. As an extension of the S&OP process, High Impact established a demand-driven supply chain model featuring adaptive inventory right-sizing algorithms for finished goods, sub-assemblies, and components integrated with consumption-based procurement and production planning systems. As a result, we have driven a significant improvement in inventory levels while maintaining best-in-class on-time delivery performance. Through the design and implementation of these processes and systems, we transformed a team that had been struggling in the post-COVID era into a high-performing, well-aligned operation.

High Impact’s training and consulting services provided a great opportunity for us to understand the concepts of Demand Flow Technology and implement our new line design that generated benefits within our Korean production facility. During our implementation, High Impact provided continual feedback, mentoring, and coaching, leading to a deeper understanding and measurable operational benefits. They delivered excellent service through all phases of training and our DFT project that extended beyond contractual obligations to ensure continued success. They are a trusted partner that we intend to continue working with.

A lot of the positive developments using Demand Flow Technology (DFT) in our manufacturing plant would not have been possible without your support!

A new, state-of-the-art headquarters facility warranted a world-class manufacturing and service operation. We were not looking for incremental change; we needed step-function-level improvement. High Impact Coaching & Strategies brought extensive hands-on experience and a proven history of results, and they delivered. You gave us great vision and insight to make "High Impact" changes both in our processes and, more importantly, in the long-term capabilities of our team. Always a pleasure working with you! We all learned a ton.

Our product mix ranges from extremely high mix, low volume to low mix, medium volume. We selected Demand Flow Technology as the foundation for Manufacturing and Supply Chain due to its flexibility in supporting product mix volatility. DFT provides our teams with a common language for planning and staging material across the supply chain and within the factory. Our customers require agility and speed in the delivery of quality products, while our stakeholders require disciplined cash conservation through inventory strategies. DFT is the platform that enables us to meet these requirements.

Case Study

Advanced Energy Industries, Inc., is a high-tech manufacturer specializing in power conversion solutions utilized in thin-film plasma manufacturing and solar energy generation. This case study reviews the work that was completed in their facility located in Shenzhen China and the improvements that they have achieved.

Customer Expectations vs. Manufacturing Capabilities

Our general experience when we walk into a new company is that there is a huge gap between the expectations of the customer and the capabilities of production.

In the factory, actual work content is probably measured in seconds, minutes or hours, not the multiple days or weeks that products seem to take through manufacturing. With the cumulation of supply and manufacturing delays, the reality of actual customer demand is further distanced from the daily plant performance and execution.

Traditional scheduling techniques are embedded as the planners’ method of choice for many companies. The master schedule, overly reliant on inaccurate forecasts, mirrors the unresponsive nature of the factory. Outdated MRP principles and a factory focused silo-based lean initiatives contribute little to the flexibility and speed and response needed to keep pace with variable and sometimes volatile customer demand. As a result, companies are only able to maintain customer service levels through holding inventory buffers throughout production and in Finished Goods.

Balance – Alignment – Agility – Responsiveness

The goal of any manufacturing company is to have an agile production facility that is adaptive to changes in daily demand and one that is aligned as closely as possible to the market. Your facility needs to become truly Demand Driven and transition itself away from the business processes that force production environments to add significant costs to the business.

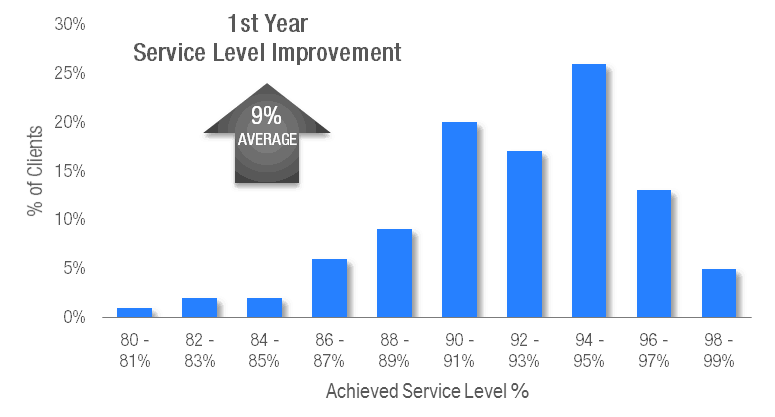

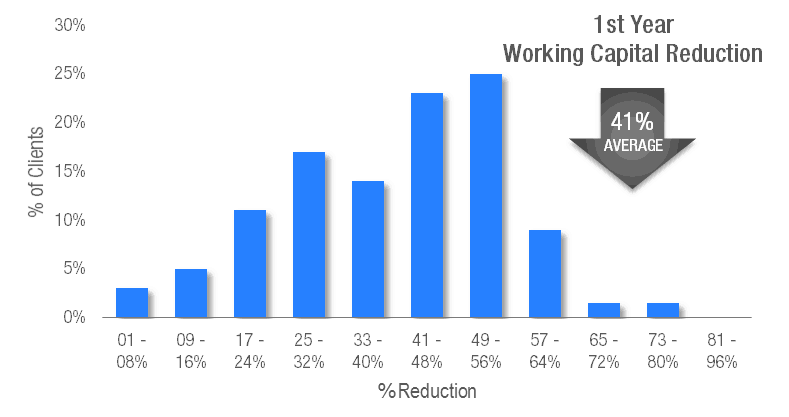

Demand Flow Technology manufacturing environments are designed to be balanced to support agility and flexibility. Through design, over-production is eliminated, flow is established, reducing lead times and as a consequence, WIP and Finished Goods inventories are reduced improving the organization’s Working Capital position. Customer service levels are increased as a direct result of improved planning processes, improved levels of response through manufacture, agility, and adaptability to changes in demand.

Our Demand Driven strategies will enable your manufacturing operations to meet market-driven requirements drastically reducing response times, inventory requirements and waste creating a competitive advantage in the marketplace. Our Demand Driven strategies have their foundation in Demand Flow Technology enabling your organization to respond faster and more efficiently to the needs of your customers.

High Impact’s DFT methodologies enable companies to synchronize every manufacturing process to changing demand on a daily basis. We create mixed model flow with optimized resources within manufacturing, supported by dynamic material replenishment strategies to achieve a faster and repeatable response to daily demand. With more repeatable response cycles that are synchronized to the daily demand, we can transform global organizations, enabling them to gain control of previously out-of-balance factories, high levels of inventory, and spiraling operational costs.

Case Study

Industrial Scientific Corporation is the global leader in gas detection products and related services that keep workers safe in hazardous environments. This Demand Flow Technology case study documents the work undertaken during 2014 and 2015 to consolidate the manufacturing and service operations, redesign product flow in addition to fitting the new operations environment into effectively less space within a new facility.

Newsletter Sign Up

Keep up-to-date on what's happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!

Email

info@highimpactcs.com

Address

High Impact House,

Ashby de la Zouch,

Leicestershire

LE65 1SP. UK

Telephone

US (Toll Free): +1 888 841 8621

UK Telephone: +44 7832 270 381