Demand Driven Supply Chain Networks

Supply chain planners and your company are under tremendous pressure. Pressure to meet rising customer expectations for product availability and order lead-time, to reduce supply chain costs, and to outperform competitors; all in an effort to capture market share. At the same time, market forces are increasing supply chain network complexity, push for efficient supply chains results in supply response becoming more vulnerable to disruption; while fragmented markets and product proliferation foster higher demand uncertainty. Accurate forecasts are becoming harder to create and business processes are becoming less repeatable… putting your supply chain into a state of chaos to complete an order!

This is what we call the New Normal – Read More

In this new Normal, well-architected Demand Driven supply chains are highly flexible and agile, adapting quickly to changes in demand and customer preferences. The focus is on customer demand, and the supply chain is designed to be highly responsive to that demand. This means that inventory levels are kept low, and production is only initiated when there is actual demand for the product. The goal is to minimize waste, reduce costs, and increase efficiency by producing only what is needed when it is needed. By being able to quickly adapt to changes in customer preferences or market conditions, companies can improve their customer satisfaction and increase their market share. Essentially the Demand Driven supply chain becomes a sustainable market advantage that enables you to significantly outperform your competitors in customer service, operating costs, and free cash flow.

At High Impact, we work with our clients to design and manage Demand Driven Supply Chain solutions driving sustainable global improvements through lead time compression, reduced inventory with increased service levels, reduced working capital, and improved cash flow.

Supply chain planners and your company are under tremendous pressure. Pressure to meet rising customer expectations for product availability and order lead-time, to reduce supply chain costs, and to outperform competitors; all in an effort to capture market share. At the same time, market forces are increasing supply chain network complexity, push for efficient supply chains results in supply response becoming more vulnerable to disruption; while fragmented markets and product proliferation foster higher demand uncertainty. Accurate forecasts are becoming harder to create and business processes are becoming less repeatable… putting your supply chain into a state of chaos to complete an order!

This is what we call the New Normal – Read More

In this new Normal, well-architected Demand Driven supply chains are highly flexible and agile, adapting quickly to changes in demand and customer preferences. The focus is on customer demand, and the supply chain is designed to be highly responsive to that demand. This means that inventory levels are kept low, and production is only initiated when there is actual demand for the product. The goal is to minimize waste, reduce costs, and increase efficiency by producing only what is needed when it is needed. By being able to quickly adapt to changes in customer preferences or market conditions, companies can improve their customer satisfaction and increase their market share. Essentially the Demand Driven supply chain becomes a sustainable market advantage that enables you to significantly outperform your competitors in customer service, operating costs, and free cash flow.

At High Impact, we work with our clients to design and manage Demand Driven Supply Chain solutions driving sustainable global improvements through lead time compression, reduced inventory with increased service levels, reduced working capital, and improved cash flow.

Deployment of a Demand Driven Supply Chain

Our consulting team at High Impact are well versed in these issues. Working directly with our global clients we understand first-hand the challenges and issues that supply chain professionals have to overcome on a daily basis as they attempt to contend with poor forecasts, mediocre supply performance, and volatile demand while meeting the needs of increasingly demanding customers. Working across entire supply networks and multi-tier suppliers we develop specific Demand Driven supply chain solutions to enable organizations to work towards becoming Demand Driven Adaptive Enterprises. Implementation of a demand Driven Supply Chain provides network-wide visibility and control enabling lead time compression, reduced inventory with increased service levels, reduced working capital, and improved cash flow.

We have a proven history of transforming entire supply networks delivering sustainable and impactful impact creating a strategic weapon and a competitive advantage in the marketplace.

Transform your global supply chain network to deliver a Return on Capital Employed (inventory) supporting the needs of your customers. Achieve lower levels of inventory than you would imagine while increasing your service level performance through the deployment of High Impact’s best-in-class Demand Driven supply chain methodologies.

Unlocking the Capabilities of Your Supply Chain

Through the deployment of our transformation programs, your business will benefit from:

Up to 80%+

Up to 65%

Up to 100%

Sandy Goodwin of High Impact Coaching & Strategies brought structure and measurable impact to our operations through the invaluable tools and processes he developed. We have successfully designed and implemented a robust Sales & Operations Planning (S&OP) process, significantly enhancing our ability to balance demand and supply across the business. Sandy’s guidance in customer and product segmentation, along with the definition of product families and the implementation of a robust statistical forecasting model, has greatly simplified and improved the accuracy of our demand planning. As an extension of the S&OP process, Sandy established a demand-driven supply chain model design featuring adaptive inventory right-sizing algorithms for finished goods, sub-assemblies, and components that are integrated within Consumption-Based Procurement and Production planning systems. As a result, we have driven a significant improvement in inventory levels while maintaining best-in-class on-time delivery performance. Through the design and implementation of these processes and systems, we transformed a team that had been struggling in the post-COVID era into a high-performing, well-aligned operation.

High Impact’s consulting services provided a great opportunity for us to understand the concepts of Demand Flow Technology and to implement our new Line Design that generated benefits within our Korean production facility. High Impact provided continual feedback, mentoring, and coaching leading to a detailed understanding and operational benefits that would not have been possible through education alone. They provided an excellent service through all phases of our project that continued beyond their contractual obligations ensuring our continued success. They are a trusted company that we will continue to partner with.

A lot of the positive developments using Demand Flow Technology (DFT) in our manufacturing plant would not have been possible without your support!

A new state of the art headquarters facility warrants a world-class manufacturing and service operation. We weren’t looking for an incremental change, we needed step function level change. High Impact Coaching & Strategies offered extensive hands-on experience and a history of results that met our needs…and they delivered.

Our product mix ranges from extreme high mix, low volume to low mix, medium volume. We selected Demand Flow Technology (DFT) as the foundation for Manufacturing and Supply Chain because of its flexibility in supporting the volatility of our product mix. It provides our teams with a common language for planning and staging material in the supply chain and within the factory. Our customers require agility and speed for delivery of quality products and our stakeholders require cash conservation with our inventory strategies. DFT is our platform to achieve these requirements.

Responsive & Optimized Supply Chain

For companies to compete in today’s marketplace, the process of planning and executing the entire supply chain must be decoupled from the forecast. A responsive supply chain network that enables visibility, control, agility, lead time compression, reduction in inventory levels, improvement of customer satisfaction, and a Return on Investment on working capital will only be possible when it is aligned with the needs of the marketplace and actual demand.

At the core of our supply chain programs is the creation of a Demand Driven Organization that leverages best-in-class Demand Driven methodologies of Demand Flow Technology in the factory and Demand Driven Supply Chains enable our clients to de-risk their supply chain, reducing lead times, inventory levels, and operational costs while improving customer service. The effect of which will be increased visibility and control of the supply chain, driving substantial improvement to the bottom line.

Further risk and liability are removed from the supply network through the creation of a Demand Driven Procurement Strategy and Supplier Integration Programs. The key part of these strategies is to adopt a total cost of ownership methodology across the organization’s entire supply chain while developing innovative inventory policies and optimized demand signals; minimizing the risk of crippling supply-chain disruptions.

We pay particular attention to the creation of responsive agile supply chain networks that are synchronized to market demand requirements through the compression of supply chain lead times, positioning, and right-sizing of strategic inventory, and the decoupling of consumption and supply thereby absorbing the inherent variabilities in demand and supply.

Working with High Impact you will introduce specific demand management strategies to establish Demand Driven supply chains that will meet the increased expectations of your customers for product availability, reduced order lead time, reduction in supply chain costs creating a sustainable market advantage that will enable your organization to significantly outperform its competition.

Case Study

67% reduction in Lead Time and 41% reduction in Working Capital

Advanced Energy Industries, Inc., is a high-tech manufacturer specializing in power conversion solutions utilized in thin-film plasma manufacturing and solar energy generation. This case study reviews the work that was completed on their Supply Chain and the improvements that they have achieved.

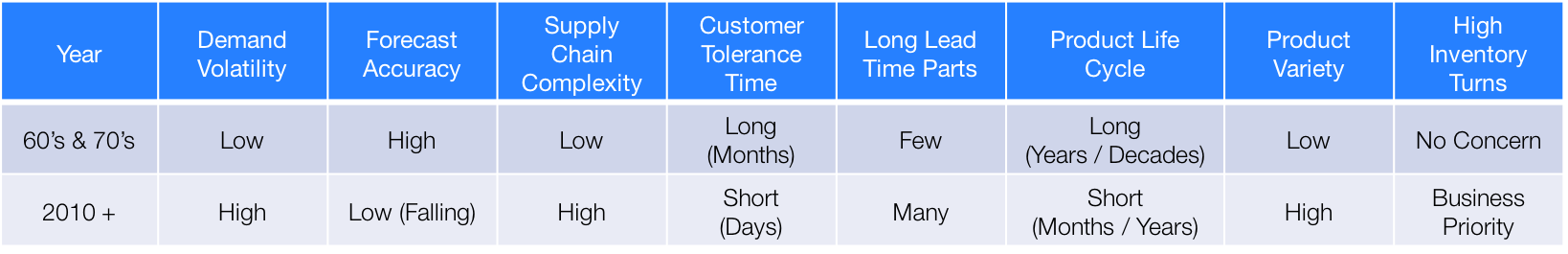

Today’s The New Normal

Since the inception of MRP, supply chains have dramatically evolved from being simple linear based chains into more complex multi-node global supply networks. As network complexity has increased so too have the volatility levels in demand and supply. The synchronization of supply and demand is further complicated as customer tolerance times decrease, the number of parts with long lead times increase, product life-cycles become shorter and product complexity increases. Quite simply these are the economic realities of doing business today or the “New Normal”.

Experienced across all countries, across all industries, and by small and large companies alike, the effects of the New Normal can be summarized as:

- Excess inventory consuming cash and space

- Stock-outs delaying customer orders affecting customer service levels

- High expedite expenses driving up operational costs

- Poor forecast accuracy used to manage long lead time parts

- Demand volatility forcing constant changes to supplier and production schedules amplifying supply disruptions

- Lack of capacity in supply chains and manufacturing

- Reliance on error-prone Excel spreadsheets

- Stressed supply chain professionals attempting to plan and execute a broken supply chain

At High Impact, our team is well versed in these issues and working with our clients we create optimized supply networks where you will experience overall inventory reduction, elimination of shortages enabling customer service to dramatically improve providing your business with a competitive weapon against the competition.

Newsletter Sign Up

Keep up-to-date on what's happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!

Email

info@highimpactcs.com

Address

High Impact House,

Ashby de la Zouch,

Leicestershire

LE65 1SP. UK

Telephone

US (Toll Free): +1 888 841 8621

UK Telephone: +44 7832 270 381