What is DDMRP?

Demand Driven MRP (DDMRP) is the world standard for Demand Driven planning, scheduling, and execution of the entire supply chain network; from end users and distribution to manufacturing and multi-tiered suppliers. It is a Multi-Echelon Material and Inventory Planning and Execution system that dynamically sizes and adapts supply networks and production systems through sensing changes in actual demand patterns and supply responsiveness. Inventory is seen as strategic and decouples the entire supply network to absorb inherent supply chain variabilities and demand volatility enabling visibility, control, responsiveness, and agility.

DDMRP combines some of the relevant aspects of Material Requirements Planning (MRP) and Distribution Requirements Planning (DRP) with the pull and visibility emphases found in Lean and the DFT and variability reduction through the incorporation of Six Sigma. Through innovation, these elements are brought together within DDMRP creating planning, scheduling, and execution tools that actually work within today’s New Normal.

DDMRP will not solve all supply chain problems, however, it will provide supply chain performance improvement in environments where there is demand volatility and supply variability coupled with cumulative lead times that are longer than the customer is willing to wait. DDMRP is transparent, easily interpreted, intuitive, consistent and sustainable planning and execution system that will also help mitigate against business risk. If companies are going to succeed they must adapt to today’s business landscape. Failure to change could risk the future of the organization, as discussed in a 2016 Harvard Business Review article.

Instead of traditional forecast driven planning, DDMRP enables businesses to track actual demand and supply and make required adjustments all in real-time which conforms to the meaning of being demand driven developed by Carol Ptak during her time at PeopleSoft:

Sensing changing customer demand, then adapting planning and production while pulling from suppliers – all in real time!

The Planning and execution of the entire supply chain must be aligned and synchronized to the needs of the market. The organization must become Demand Driven to establish an optimal supply chain design. DDMRP right sizes inventory, while reducing overall inventory holding across the supply chain, improves customer service levels, establishes lead time compression, and generates an overall return on investment. Average performance improvement would be expected to achieve

❯ 65% reduction in average on-hand inventory

❯ 80% reduction in lead times

❯ 100% on-time delivery performance

❯ 90% reduction in inventory obsolescence

❯ 400% improvement in inventory turns

❯ 25% improvement planner availability

DDMRP provides the tools to enable a company to become Demand Driven, achieving these significant benefits and meeting the expectations of their customers in today’s complex and volatile marketplace.

The Relationship to MRP

Material Requirements Planning (MRP) was developed in the 1950’s and 1960’s by Joe Orlicky. When MRP was brought to market in the 1970’s and Orlicky wrote the first edition of Material Requirements Planning there were only 700 companies in the world actually using MRP. In his book, Joe highlighted a need to overhaul how a business plans and manages both inventory and resources. By the year 1990, over 1 million companies were using MRP with little change from its original concept.

Industry is now presented a new dilemma as the circumstances that drove Orlicky’s original design have dramatically changed. Since 1970 when Orlicky’s model was launched, Forecasts have gotten worse, Supply Chain complexity has increased, customer tolerance has decreased and inventory has become a priority. These new age challenges have led to the inventory oscillation witnessed in MRP systems today. The levels of demand and supply variability that exist in the 21st Century are further compounded by the inabilities of MRP to provide reliable and appropriate information for today’s supply chain planners.

The answer to this common problem is Demand Driven Material Requirements Planning (DDMRP), defined as a multi-echelon inventory and planning system that senses the shape of customer demand, then adapting planning and production systems all while pulling from suppliers in real time. [adapted from the Demand Driven Institute 2009].

DDMRP provides companies with the operational planning and execution tools to work in today’s “New Normal” where forecasts have gotten worse, supply chain complexity has increased, customer tolerance has decreased and inventory has become a major priority. DDMRP is rapidly becoming the world standard for the emerging Demand Driven methodology in planning, scheduling and execution of the entire supply chain from retail and distribution to manufacturing and multi-tiered suppliers.

DDMRP is the core of the Demand Driven Operating Model that provides companies with the operational planning and execution tools to revolutionize their supply chains, right-sizing inventory at strategic locations throughout the entire supply network while dampening supply chain volatilities at the same time. These strategic inventories decouple the entire supply network and absorb inherent variabilities and volatilities enabling visibility, control, responsiveness, and agility.

DDMRP was developed by Carol Ptak and Chad Smith the founders of the Demand Driven Inistitute as a tool that will promote and protect flow through the entire supply network. The Demand Driven Institute is an organization that is devoted to the proliferation and development of Demand Driven strategies in industry.

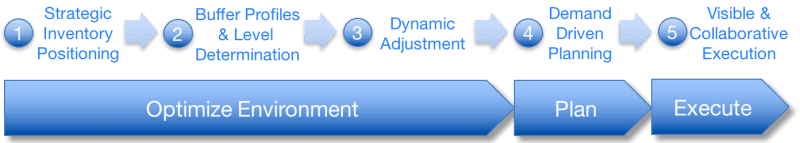

The 5 Steps of DDMRP

The first step of DDMRP is not a question of how much inventory a company should hold, or even the make/buy question. This first fundamental step of DDMRP is to identify where should inventory actually be positioned across the entire supply chain.

- Where in the supply chain, retail to distribution through to the factory and multi-tiered suppliers will we achieve maximum benefit from lead time compression and the dampening of variability?

- Where can we create maximum protection and establish decoupled independence between all points of demand and supply?

- Where will we achieve a Return on Investment?

After, and only after, the strategic locations have been identified can we then start to determine targeted inventory levels. However, we must first understand more about the parts that are being positioned at these strategic locations. The creation of Buffer Profiles will enable of parts to grouped based on particular behavioral traits of the parts in the group. The Buffer Profiles will define the part type, the level of demand and supply variability typically demonstrated and the replenishment lead time.

Once the Buffer Profiles have been established and parts assigned to these profiles, we can then size the targeted inventory levels which are referred to Buffer Zones. In DDMRP there are three specific zones that are utilized in subsequent Planning and Execution steps. The overall size of each zone will be defined based on the attributes of the Buffer Profile. A Buffer Profile defining parts with high demand variability will have a greater impact on the size of the zone more than a Buffer Profile defining parts with low demand variability.

As we know, nothing stands still for time within a supply chain. Buffer Profile attributes will change, demand patterns over time increase and decrease, and the parts being strategically positioned can change. All these changes together need to update the size of each Buffer Zone.

Dynamic Adjustments enable a company to continually optimize the inventory being positioned to ensuring maximized Return on Capital Employed (ROCE). Changes in demand patterns are sensed on a daily basis and Buffer Zones are dynamically recalculated. Such changes are incremental and don’t impact the supply chain in any manner.

Planned adjustments can be put into action to account for periods of seasonality, increasing Buffer Zones for peak seasons and product ramp up, and reducing Buffer Zones for low seasons and product planned obsolescence.

This step takes advantage of modern Demand Driven techniques which react to the dynamic nature of the Buffer Zones, availability of inventory, current demand requirements and the supply situation at each strategic inventory location.

Demand Driven Planning within DDMRP is a quick, visible and effective task. Supply order requirements are defined based on the level of depletion in current inventory, demand spike criteria, and status of current open supply orders. Inbuilt visibility enables planners to very quickly understand what is required and take most appropriate action without the need of comprehensive Excel modeling.

MRP is a forecast driven planning system and has failed to provide specific execution tools to manage open orders. The final step completes the definition of the DDMRP integrated system providing execution management tools for all open orders, whether Supplier Purchase Orders, Manufacturing Work Orders or distribution Stock Transfer Orders.

Planners are supported with an execution system that doesn’t rely on a due date but instead prioritizes all open supply based on the level of on-hand inventory depletion at each strategic location. Better to have a supplier who doesn’t stock you out than one who always delivers on time!

Solution for Excess Inventory and Stock-outs

As supply chain network complexity has increased so too have volatility levels in demand and supply through these networks. Customer tolerance is decreasing and the number of parts with long lead times are increasing.

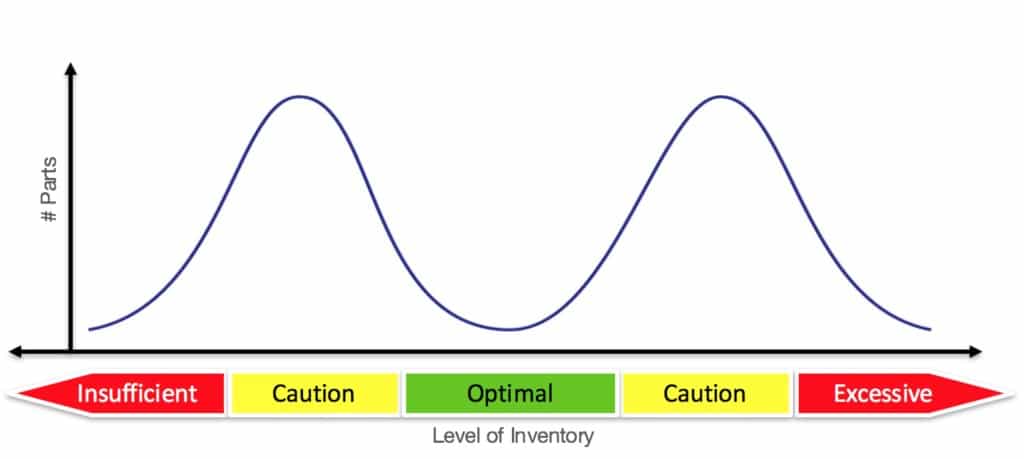

Typically, companies find they suffer from stock-outs that then affect customer service levels as well as adding time taken to respond to orders. At the same time, most companies find they allow carry excess levels of inventory affecting the financial performance. We call this Bi-Modal Inventory Distribution, too much of the wrong inventory and not enough of the right inventory.

Legacy inventory planning techniques and tools that MRP provides simply don’t work in the 21st Century. MRP is driving poor inventory and business performance.

Strategic positions through supply chain networks are protected by DDMRP dynamically controlling inventory levels and supply order generation, dampening demand distortions and supply disruptions providing a consistent availability of inventory, and maintaining stable signals to suppliers.

Demand Driven methodologies at the core of DDMRP provide a means for supply chain optimization ensuring inventory is in the right place at the right quantity at the right time. Furthermore, DDMRP will reduce inventory levels across the supply network without any erosion to service levels. In fact, DDMRP actually increases customer service levels.

Through strategic inventory realignment across the entire supply chain, DDMRP puts an end to the typical bi-modal inventory distribution suffered by most companies.

Frequently Asked Questions:

Would telling our sales and marketing team to forecast more accurately be a better option?

You have to understand the issues within the environment that you are trying to forecast. Supply chain network complexity has increased so too has volatility levels in demand and supply throughout these supply networks. In addition, customer tolerance has decreased, the number of parts with long lead times has increased, product lifecycles are shorter and product variety has increased. Even the most advanced software algorithms will still deliver inaccurate levels of forecast in this business environment.

Decoupling the generation of supply requirements from demand signals with inherent forecast errors is a must. DDMPR will ensure high levels of customer service through inventory availability; reduced inventories due to right-sizing of the right parts and the decoupling of supply lead times; and finally DDMRP will also achieve a Return on Investment deployed in working capital.

Is DDMRP just another type of Safety Stock?

Safety Stock is a supplementary inventory position designed to make up for misalignment between planned orders, actual demand and supply orders. It is designed not to be used and MRP will never consume.

DDMRP utilizes strategically positioned inventory to decouple points of supply & consumption in order to dampen variability whilst at the same time compressing lead times through decoupling of the supply and consumption nodes. All strategically positioned inventory is designed to be consumed.

Decoupling the generation of supply requirements from demand signals with inherent forecast errors is a must. DDMPR will ensure high levels of customer service through inventory availability; reduced inventories due to right-sizing of the right parts and the decoupling of supply lead times; and finally DDMRP will also achieve a Return on Investment deployed in working capital.

Will DDMRP only work with Make-to-Stock?

No, DDMRP works with all types of manufacturing strategies; Make to Stock, Make to Order, Engineer to Order, etc.

However, inventory has to be stocked at some point in the supply chain if lead times to the customer are to be reduced. Waiting three months for the supply of inventory before you start assembly of the customer order will be based whether the customer is willing to wait. Generally, the customer will not be willing to wait for you to procure inventory, so inventory needs to be maintained at some locations in the overall supply chain. DDMRP will ensure that inventory is right-sized for the right parts at all strategic locations.

Decoupling the generation of supply requirements from demand signals with inherent forecast errors is a must. DDMPR will ensure high levels of customer service through inventory availability; reduced inventories due to right-sizing of the right parts and the decoupling of supply lead times; and finally DDMRP will also achieve a Return on Investment deployed in working capital.

How can you reduce inventory levels whilst increasing service levels?

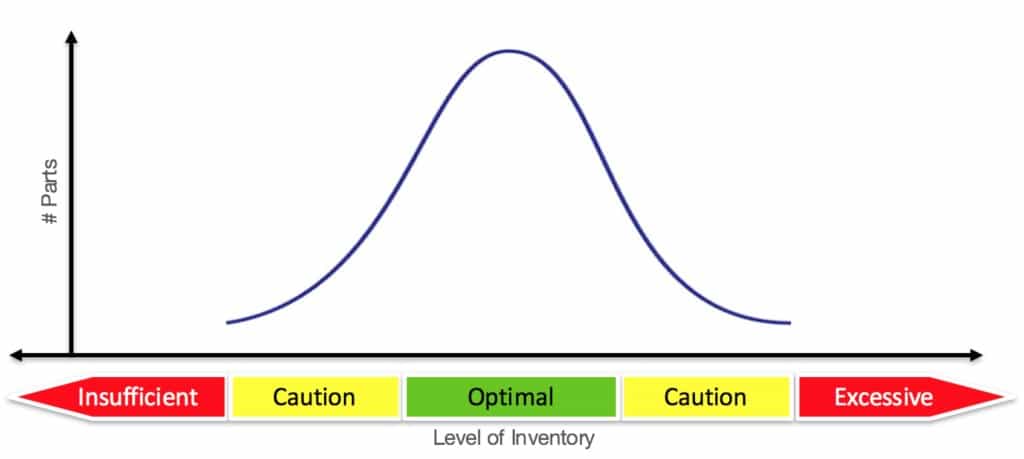

Unlike any inventory reduction program, DDMRP is a complete planning and execution methodology that is the backbone of the Demand Driven Operating Model (DDOM). As described in the 5 Steps of DDMRP, first we need to establish strategic inventory position to decouple points of supply & consumption. The dynamic buffer zones are then defined that will then automatically establish the optimum levels of inventory based on the current market conditions.

Decoupled strategic inventory that is dynamically right-sized will ensure appropriate availability of inventory, reduce lead time, and absorb the daily supply chain variabilities found in demand distortion and supply disruption.

Decoupling the generation of supply requirements from demand signals with inherent forecast errors is a must. DDMPR will ensure high levels of customer service through inventory availability; reduced inventories due to right-sizing of the right parts and the decoupling of supply lead times; and finally DDMRP will also achieve a Return on Investment deployed in working capital.

Will DDMRP just push inventory back to the supplier?

No. DDMRP will reduce inventories across the supply network, not just in your company. This is achieved by positioning inventory at strategic locations.

DDMRP can easily be applied to all current inventory locations, such as those parts currently held in as Raw Materials/Purchased Parts and in Finished Goods. DDMRP will dynamically right-size the appropriate levels of inventory at these locations without asking suppliers to hold all your inventory for you.

Based on your supplier relationships, you may wish to introduce the supplier to the overall benefits that DDMRP will achieve for a business. Even if suppliers don’t implement DDMRP immediately, experience shows their performance will actually improve through stability of demand signaling and a reduction in demand distortion enabling suppliers to improve their planning and execution process.

The Demand Driven Institute’s endorsement of TheONE was important to us as it not only recognizes our software in the same way early MRP developers received Joe Orlicky’s endorsement but also indirectly acknowledges our work in the last 10 years establishing Demand Driven supply chains around the world. TheONE combats the most common problem our clients were continually facing…MRP failed to provide appropriate and reliable information. TheONE will provide companies with the operational and tactical planning and execution tools they require to operate a demand driven supply chain in the 21st Century.

DDMRP Software

High Impact Coaching & Strategies has decades of experience promoting Demand Driven strategies across our customers’ factories and global supply chains. As a provider of Demand Flow Technology (DFT) consulting and education, supply chain consulting and our software services we provide our customers with the capabilities to create flow, compress lead times and reduce inventory generating sustainable bottom-line benefits.

We provide our customers with cutting-edge Demand Driven solutions focused on enabling flow through the entire supply chain. Our world-class service and thought leadership mixed with a blend of real-world experience and practical training techniques will help you achieve your financial objectives.

The DDMRP module within TheONE software platform is endorsed by the Demand Driven Institute as being fully DDMRP Compliant. TheONE enables your planners to configure and manage a Demand Driven supply chain with the operational planning and execution tools right-sizing inventory throughout the entire supply network providing visibility, control, responsiveness, and agility.

As an Affiliate to the Demand Driven Institute, High Impact Coaching & Strategies abides to maintain strict standards in the delivery of education, training and implementation of Demand Driven MRP, the Demand Driven Operation Model and the Demand Driven Adaptive Enterprise Model.

Newsletter Sign Up

Keep up-to-date on what's happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!

Email

info@highimpactcs.com

Address

High Impact House,

Ashby de la Zouch,

Leicestershire

LE65 1SP. UK

Telephone

US (Toll Free): +1 888 841 8621

UK Telephone: +44 7832 270 381