Sales and Operations Planning (S&OP) is a powerful tactical business planning approach that aligns the demand and supply sides of a business while managing financial and operational objectives. Its whole purpose is to create a balance between demand and supply, ensuring that resources are optimized, inventory costs are minimized, customer service is enhanced, and revenue growth is achieved. S&OP holds a vital role in driving organizational success.

In the first of two articles, the fundamental aspects of S&OP were introduced with a clear understanding of each of the 5 steps of S&OP before outlining many of the benefits that can be gained from adopting S&OP as a business tactical process.

In this second part, we will examine potential pitfalls that organizations may encounter during implementation and then finally, we will wrap up with a compelling conclusion that emphasizes the significance of S&OP and its potential impact on the prosperity of businesses.

The Pitfalls of S&OP

S&OP is not without challenges and risks that organizations may encounter when implementing and operating S&OP. Some of the common pitfalls of S&OP are:

Lack of Commitment

Successful implementation of S&OP requires a strong commitment from all levels of the organization, and in particular top management. Without a clear vision, direction, and support from the top, S&OP may fail to generate sustained support and effort from the operational teams hindering the effectiveness of the process.

Lack of Collaboration

S&OP relies heavily on cross-functional collaboration and communication among all the stakeholders. If there is a lack of collaboration between departments, siloed thinking, or a lack of shared goals, it can impede the effectiveness of S&OP. Departments may work in isolation, leading to misalignment and suboptimal decision-making.

Lack of Alignment

S&OP requires a close alignment between the strategic plan and the operational plan. This is achieved through the alignment of demand, and supply, with the financial goals. However, if there is a lack of alignment between departments, conflicting objectives and priorities can arise. Misalignment can lead to suboptimal decision-making, inefficient resource allocation, and missed opportunities for improvement.

Lack of Agility

Market dynamics and customer demands can change rapidly. If the S&OP process is rigid and lacks agility, it may struggle to respond effectively to these changes. Lack of flexibility can result in slow decision-making, inability to adjust plans, and missed opportunities. Without a robust feedback loop and adjustment mechanism, S&OP may become outdated, irrelevant, and ineffective.

Inadequate Data and Information

S&OP relies on accurate and timely data from various sources. If organizations lack the necessary data infrastructure, data quality, or access to relevant information, it can hinder the accuracy and reliability of the planning process.

Insufficient Technology and Tools

S&OP often requires sophisticated software tools and technology to gather, analyze, and visualize data. Inadequate technology infrastructure or outdated tools can limit the effectiveness of S&OP and hinder the ability to make informed decisions.

Resistance to Change

Implementing S&OP may require changes to existing processes, roles, and responsibilities. Resistance to change from employees or stakeholders can undermine the successful adoption of S&OP. Lack of buy-in, fear of job security, or resistance to new ways of working can pose significant challenges.

Inaccurate Demand Forecasting

S&OP heavily relies on accurate demand forecasts. If demand forecasting is flawed, it can lead to inefficient inventory management, production imbalances, and missed sales opportunities. Inaccurate forecasting can stem from inadequate historical data, insufficient market insights, or limited collaboration among stakeholders.

Overemphasis on Internal Metrics

Focusing solely on internal metrics, such as cost reduction or internal efficiencies, without considering external market factors and customer needs, can lead to suboptimal outcomes. S&OP should strike a balance between internal goals and external market realities.

Lack of Continuous Improvement

S&OP is an iterative process that requires continuous monitoring, evaluation, and improvement. Organizations that fail to consistently review and refine their S&OP process may miss opportunities for optimization and fail to adapt to changing business conditions.

Conclusions

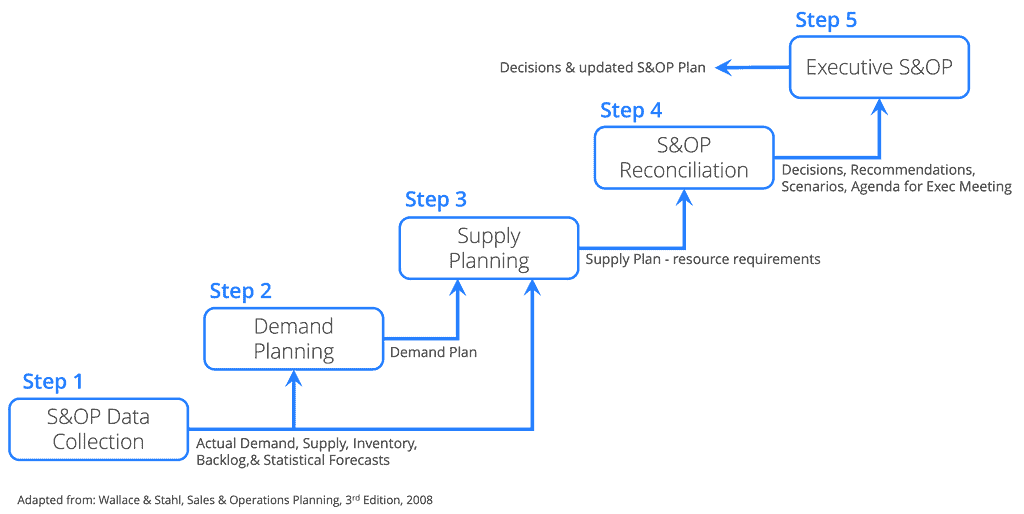

Sales and Operations Planning (S&OP) enables businesses to harmonize demand and supply, optimize resources (people, machines, and materials), and achieve their financial and operational goals. By aligning cross-functional collaboration, data-driven decision-making, and a structured approach, S&OP brings a wide array of benefits to organizations. S&OP is a process of 5 major steps that follow a monthly cycle that consists of Data Collection, Demand Planning, Supply Planning, S&OP Reconciliation (or Pre-S&OP), and ends with the Executive S&OP meeting.

Through the implementation of S&OP, businesses can enhance customer service, reduce inventory costs, increase revenue, and improve overall profitability, ultimately gaining a competitive edge. S&OP enables efficient utilization of resources, facilitates quick and adaptive responses to market fluctuations, and enhances the efficiency of the supply chain. Furthermore, S&OP supports effective risk management, boosts forecast accuracy, and fosters improved collaboration and communication across different departments within the organization. In summary, S&OP empowers businesses to thrive by optimizing operations and achieving successful outcomes.

Through the implementation of S&OP, businesses can enhance customer service, reduce inventory costs, increase revenue, and improve overall profitability, ultimately gaining a competitive edge. S&OP enables efficient utilization of resources, facilitates quick and adaptive responses to market fluctuations, and enhances the efficiency of the supply chain. Furthermore, S&OP supports effective risk management, boosts forecast accuracy, and fosters improved collaboration and communication across different departments within the organization. In summary, S&OP empowers businesses to thrive by optimizing operations and achieving successful outcomes.

However, it is important to be aware of potential pitfalls when implementing and operating S&OP. These challenges include the lack of commitment and collaboration, inadequate alignment between departments, inflexibility, insufficient data, and technology, resistance to change, inaccurate demand forecasting, overemphasis on internal metrics, and the absence of continuous improvement. Addressing these pitfalls and implementing effective strategies to overcome them is crucial for the successful adoption and sustainability of S&OP.

In a dynamic business environment, organizations that embrace S&OP and proactively address its challenges can unlock significant value. By leveraging the benefits of S&OP and mitigating its pitfalls, businesses can achieve operational excellence, improve customer satisfaction, and drive sustainable growth and success.

Demand Driven Supply Chain Solutions

Wherever you manufacture, High Impact Coaching & Strategies can help you to reduce your Cost of Goods Sold by up to 23%, increase productivity by up to 69%, reduce manufacturing lead times by up to 90%, and increase capacity by up to 66%. By ALIGNING manufacturing and the supply chain to customer demand, promoting AGILITY to meet customer demand volatility, and ADAPTING capability as change takes place, we deliver exceptional results for our clients worldwide.

We provide our customers around the world with solutions that create synchronization and balance through the entire supply chain creating a competitive advantage in their marketplace. Demand Driven supply chains drive operational capabilities generating sustainable bottom-line benefits.

In the factory, Demand Flow Technology focuses on the design and operation of the manufacturing flow. It is a comprehensive mathematical-based methodology that balances resource capability to actual, or planned demand, enabling a company to improve response capability to customer orders, reducing lead time, working capital, and Cost of Goods while improving productivity and overall customer satisfaction. DFT is the framework that enables manufacturing to be adaptive to daily changes in the required mix and actual demand.

Demand Driven supply chains focus on the optimization of strategically positioned inventory that absorbs demand volatility and supply variation we see in the bullwhip creating stability in supply downstream and demand creation upstream. Dynamic and statistically designed inventory levels based on current market conditions and will reduce overall inventory across the entire supply chain while improving customer service levels and response capability. By being able to quickly adapt to changes in customer preferences or market conditions, Demand Driven companies can improve their customer satisfaction and increase their market share.

For further information or to inquire how you can implement Demand Driven Supply Chains please email us at info@highimpactcs.com or send a message via our contact page.

Manufacturing & Supply Chain Information

Previous Insights from High Impact Coaching & Strategies:

- What is Demand Flow Technology

- What Is The Difference Between Lean and Demand Flow Technology?

- The Tools of Demand Flow Technology

- How Demand Flow Technology Impacts The Health of Your Business (1st of 3 Parts)

- Cash Flow Generation is a Priority (1st of 2 Parts)

- Review of a Recent Demand Flow Technology Implementation

- What is Supply Chain Management?

- Supply Chain Planning & Engineering

- The Supply Chain Methodology That is DDMRP

- What is DDMRP?

- MRP – Solution or Problem

- A Solution to Excess Inventories, Stocks-Outs & Poor Customer Service?

- Adapt or Die – Become Demand Driven

- Supply Chain Brain: DDMRP as an Emerging Disruptive Supply Chain Capability

- What Does VUCA Mean?

Overview of High Impacts’ Demand Driven strategies that will transform your factories and supply chain network:

LinkedIn Information:

Talk to us today to learn more about how we can help your organization become Demand Driven through the adoption of our Demand Driven methodologies, DDMRP and Demand Flow Technology.

Newsletter Sign-Up

Keep up-to-date on with what’s happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!