Supply Chain Planning

Supply Chain planning and supply chain management are terms generally used to describe the flow of goods from the supplier into the factory. At High Impact Coaching and Strategies, we view your supply chain as being from beyond your customer through your factory to beyond your suppliers.

The role that supply chain planning performs in a business is highly important. The objective is to anticipate the needs of the market while also understanding how you can create value. The challenges are:

- Identify who your customers are and what products they want.

We analyse your business from a dual point of view concerning customers and also product portfolio. This helps us to understand what is adding value to the business and what is driving significant complexity and cost to serve.

- Understand what your business resources and capabilities are and what you will need in the future.

Forget trying to predict requirements. With our Demand Driven Flow Technologies (DDFT) and Demand Driven Supply Chain solutions, we evaluate current capabilities and resources to define what is required to meet the requirements of your customers. Once we know what is required, we establish Demand Driven flow within the factory and through the supply chain.

- Understand the environment that your business is operating within.

What are the current economic issues affecting your business sector, who are your competitors and what are they doing?

Consolidating these challenges can make it almost impossible to understand what the future will be like. However, as mentioned at High Impact we work with our clients to develop a select number of scenarios that filter back to the business strategies of the organization. Each scenario enables us to help shape your factory and supply chain. In doing so, we can establish what levels of investment are required whether that’s machine processes, employees, technology, how much inventory and where to position it throughout your supply chain.

Supply Chain Engineering

Once you know what you want and need to change you can use supply chain engineering to design the optimal environment. This can mean designing the flow within the factory using DDFT, determining inventory requirements, mapping the global flow of materials and products, and where to locate facilities.

Planning and engineering of your supply chain are important to ensure it functions well but more importantly, they’re critical to ensuring you provide value to your customers.

Demand Driven Will Drive Value

At High Impact, we believe that improved product, material & information flow, and balance through the entire supply chain along with response predictability from production facilities will enable a more agile (faster, more repeatable lead time) operation. Agile Demand Driven operations dynamically managing inventory levels across your entire supply chain will significantly reduce the impact that demand volatility and supply variability have on the supply chain. A Demand Driven operation will thereby establish an adaptive Demand Driven supply network with improved responsiveness, stability and consistency. Demand Driven operations utilize less space, require less working capital, have lower operating costs and enable world-class customer service lead times while being easier to manage.

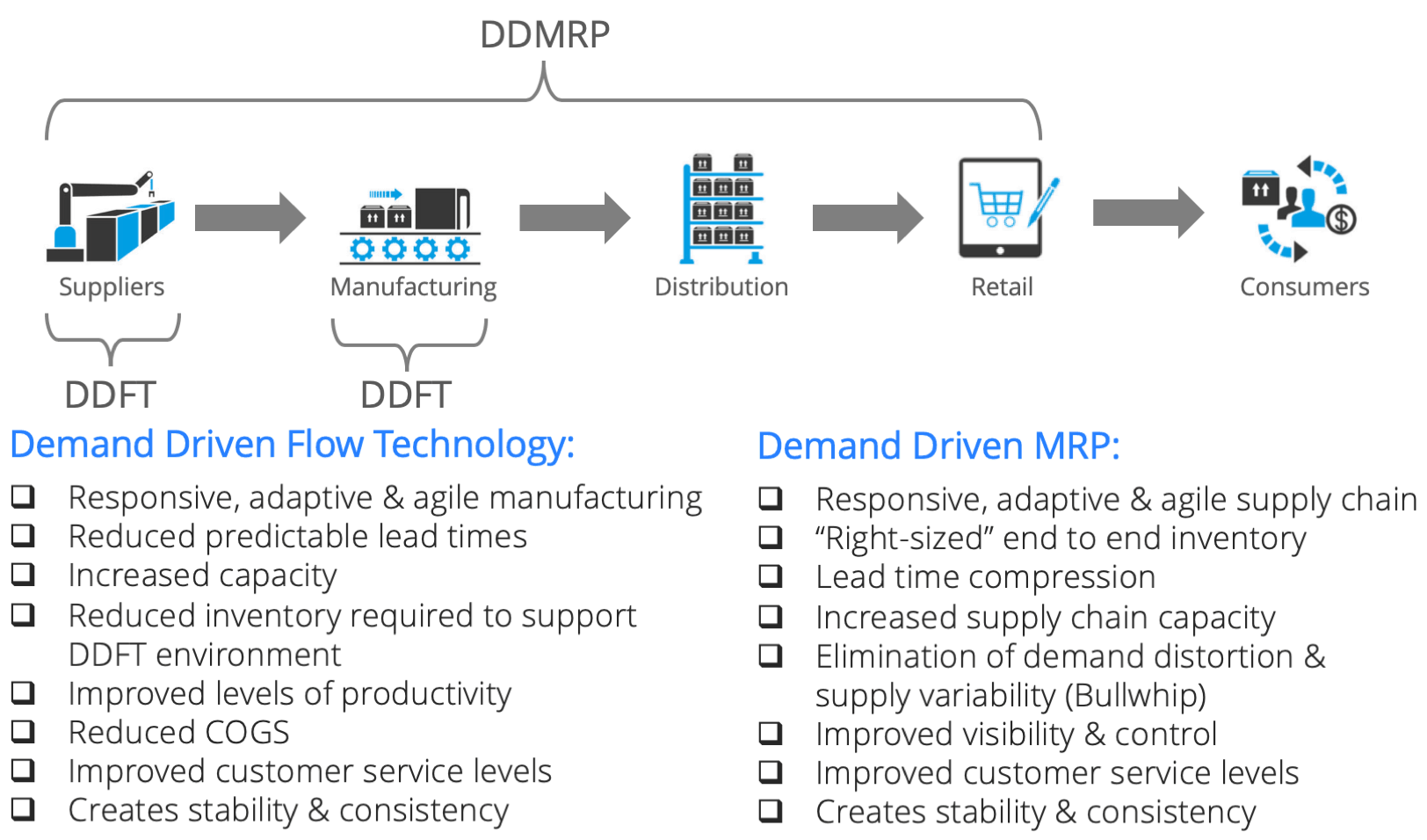

The benefits are clear, Demand Driven Flow Technology (DDFT) improves productivity, reduces lead times, inventory and Cost of Goods Sold while a Demand Driven Supply Chain (or DDMRP) will reduce overall inventory, improves material availability and lead time response.

Some companies go down the route of stocking huge amounts of inventory only to find they stocked the wrong inventory. Some will create excess capacity with the manufacturing plant so they can ramp up quickly as demand ramps up but machines sit idle. The design of the supply chain needs to be Demand Driven and based on the business model and rules, to enable the reduction/elimination of excess inventory costs, and the positioning of optimum resource capacity. A Demand Driven supply chain model will give you just that where we integrate our Demand Driven solutions of Demand Driven Flow Technology (DDFT) with Demand Driven MRP (DDMRP).

A Demand Driven Supply Chain from High Impact Coaching & Strategies will enable responsive, agile manufacturing, and end to end supply chain optimization that will reduce your costs, inventory and lead times transforming your business into a world-class Demand Driven organization at the forefront of your industry.

Demand Driven Supply Chain Management Solutions

We provide our customers around the world with solutions that create synchronization and balance through the entire supply chain creating a competitive advantage in their marketplace. Demand Driven supply chains drive operational capabilities generating sustainable bottom-line benefits.

In the factory, Demand Driven Flow Technology focuses on the design and operation of the manufacturing flow. It is a comprehensive mathematical-based methodology that balances resource capability to actual, or planned demand, enabling a company to improve response capability to customer orders, reducing lead time, working capital, and Cost of Goods while improving productivity and overall customer satisfaction. DDFT is the framework that enabling manufacturing to be adaptive to daily changes in the required mix and actual demand.

Demand Driven MRP is the planning engine that drives the supply chain and the factory. It focuses on the optimization of strategically positioned inventory along the supply chain that absorbs demand volatility and supply variation we see in the bullwhip creating stability in supply downstream and demand creation upstream. Mathematical buffer designs that dynamically optimize inventory levels based on current market conditions and will reduce overall inventory across the entire supply chain while improving customer service levels and response capability. DDMRP provides the Supply Chain Planning and Execution tools to enable a company to become Demand Driven so that it can meet the expectations of its customers in today’s complex and volatile marketplace.

DDFT and DDMRP work together using actual demand to drive the Demand Driven supply chain removing traditional reliance on forecasting to drive the supply chain. The Demand Driven Supply Chain management activities still use the forecast, but now as an input for the Demand Driven Sales & Operations Planning (DDS&OP) process. DDS&OP will adapt the supply chain model based on the various business conditions and the forecast appropriately resizing the inventory buffers. Supply orders are now generated based on actual consumption from the dynamic buffers rather than based on a forecast requirement.

For further information or to inquire how you can implement Demand Driven Supply Chains please email us at info@highimpactcs.com or send a message via our contact page.

Manufacturing & Supply Chain Information

Previous Insights from High Impact Coaching & Strategies:

- What is Demand Driven Flow Technology

- What Is The Difference Between Lean and Demand Driven Flow Technology?

- The Tools of Demand Driven Flow Technology

- How Demand Driven Flow Technology Impacts The Health of Your Business (1st of 3 Parts)

- Cash Flow Generation is a Priority (1st of 2 Parts)

- Review of a Recent Demand Driven Flow Technology Implementation

- What is Supply Chain Management?

- The Supply Chain Methodology That is DDMRP

- What is DDMRP?

- MRP – Solution or Problem

- A Solution to Excess Inventories, Stocks-Outs & Poor Customer Service?

- Adapt or Die – Become Demand Driven

- Supply Chain Brain: DDMRP as an Emerging Disruptive Supply Chain Capability

- What Does VUCA Mean?

Overview of High Impacts’ Demand Driven strategies that will transform your factories and supply chain network:

LinkedIn Information:

Talk to us today to learn more about how we can help your organization become Demand Driven through the adoption of our Demand Driven methodologies, DDMRP and Demand Driven Flow Technology.

Newsletter Sign-Up

Keep up-to-date on with what’s happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!