Does This Sound Familiar With Your Demand Flow Technology (DFT) Line?

Your Demand Flow Technology production facility is no longer meeting the needs of your business. Customer service levels have become stagnant or reduced, work in process is out of control, productivity is at its lowest for years and lead times are longer than ever and without any level of consistency.

We hear these issues quite often and until recently would generally surprise me. We hear these statements all the time from companies that have not made their Demand Flow Technology (DFT) journey. However, on this occasion, I was talking to a company that implemented DFT around five years ago and had achieved substantial bottom-line benefits.

Back in 2014, the customer service level at this particular company was spiralling out of control, productivity was low, production lead times were becoming longer and longer, and inventory was turning a little over once per year. Following a DFT implementation through their entire manufacturing facility, significant ROI was achieved as we expected; production lead times dropped by over 60%, productivity increased by 20%, WIP inventories dropped by 35% whilst achieving a 15% improvement in customer service levels. So, you can imagine my surprise when in a recent call they told me that they were no longer able to meet the needs of their customers and the Demand Driven strategies that they had deployed had all but disappeared. It was like they had gone back in time.

So, what happened?

Well, there were several reasons that this company had seemingly gone backward. However, I would say the biggest fundamental issue is that they failed to maintain and update the design for their Demand Flow Technology environment. The 5th principle of Lean, as identified by Womack and Jones in their book, Lean Thinking, is the pursuit of perfection, continuous improvement. We also discussed this in a recent Insight we wrote on Kaizen Failures:

For Kaizen to be successful, it needs to be continuous ………..no process can ever be declared perfect, there is always room for improvement.

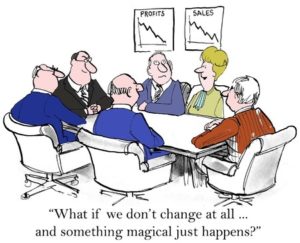

When it comes to improvement, we should never stand still.

In our Demand Driven Insight, Adapt or Die – Become Demand Driven, we also discussed a 2016 article by Harvard Business Review that raised the point that companies need to Adapt or Die to survive in the future. Continuous improvement and adapting to changes in the business landscape where simply just disregarded by this company. For several years they enjoyed the fruits of their success, market share was increasing, and significant financial savings were achieved. At the time they saw DFT as the solution to all their problems, “a silver bullet”, but failed to remember and understand that a DFT design is not good for “life”. As their gains were so great, achieving further incremental benefits from continual improvement was not important.

All DFT Lines Must Evolve

A Demand Flow Technology line is only good for as long as it meets the needs of the business. We always discuss in our Mixed-Model training and during implementations that designs typically have a life of 12 – 36 months, dependant on product maturity. Furthermore, companies should review customer demand requirements associated to the line every 6 months to ensure that the line maintains the capability to meet the needs of the market.

One of the first things I tell the C-Level suite when they decide to implement Demand Flow Technology is that the DFT environment must evolve, adapt and align to the requirements of the business now and into the future. No single design is going to accomplish this forever. Therefore, any new DFT environment must develop throughout the life of the organization to sustain performance and to enable business growth to take place. It’s going to take more than just the odd tweak here and there to ensure that your DFT line is achieving its maximum potential. Remember, you are designing the flow in your factory to achieve a particular level of daily demand for a particular mix of products. This will undoubtedly change over time.

In the next installment of this Demand Driven Insight, we discuss how a Demand Flow Technology environment should evolve over time. Read Part 2 of this Demand Driven Insight.

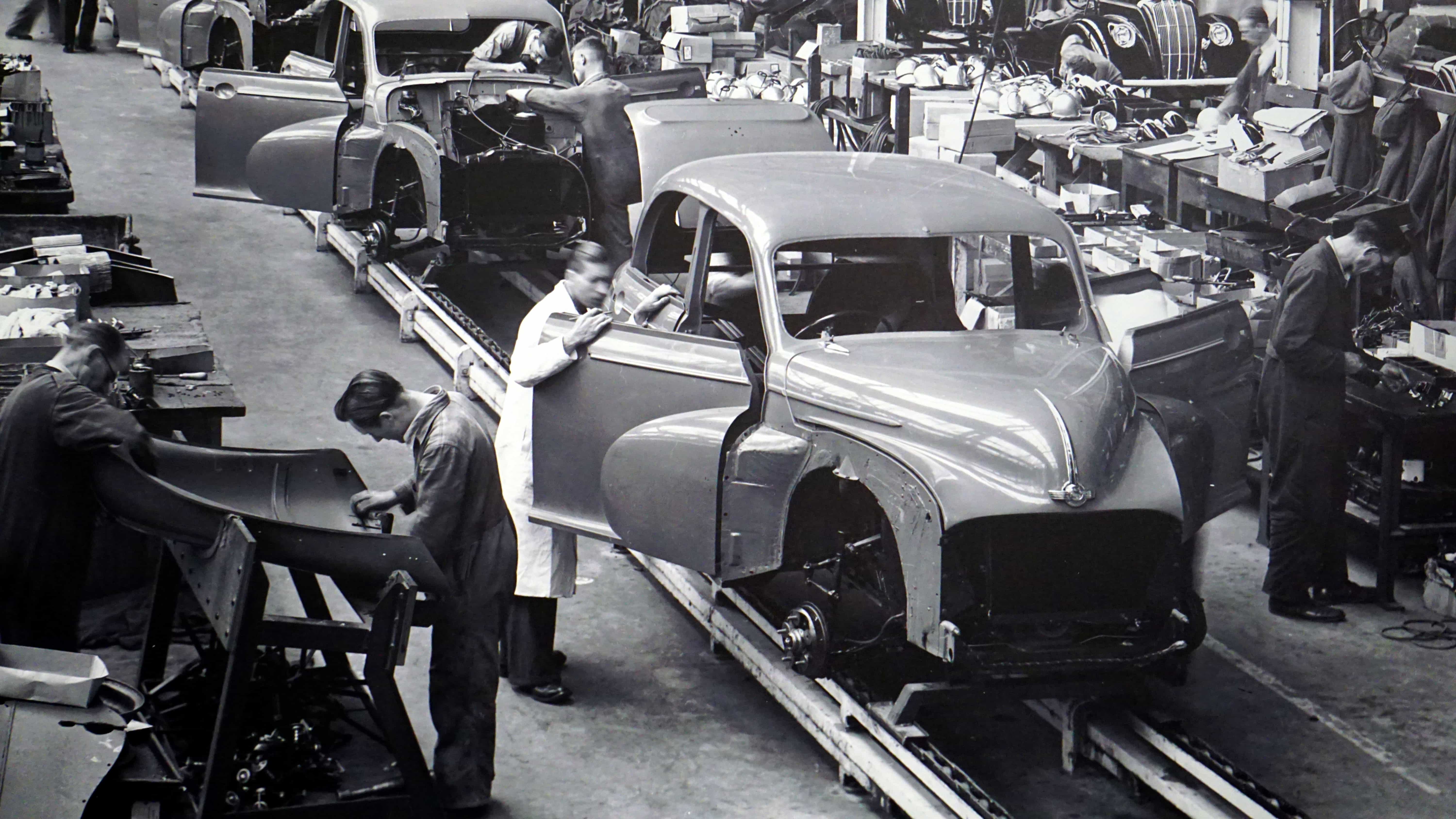

The success of Demand Flow Technology in Industry

Global organizations are being transformed, regaining control of previously unbalanced production environments along with the high levels of inventory and ever-increasing operational costs that are associated with traditional operations. Equally successful in all industries, DFT is the science behind flow manufacturing techniques utilized by leading companies such as Advanced Energy Industries, Boeing, Garmin, Hyster-Yale, Industrial Scientific Corporation, John Deere, and Nortek. The importance of Demand Flow Technology to manufacturers was stressed by the former Chairman and CEO of GE, Jack Welch when he stated “DFT is an absolute business discipline…it’s another way to simplify the business.”

Newsletter Sign-Up

Keep up-to-date on what’s happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!

Email

info@highimpactcs.com

Address

High Impact House,

Ashby de la Zouch,

Leicestershire

LE65 1SP. UK

Telephone

US (Toll Free): +1 888 841 8621

UK Telephone: +44 7832 270 381