Cash flow generation during the COVID-19 New Normal is critical for survival. In the second of this 2-part series, we develop further how the tools of Demand Flow Technology can be applied to manufacturing and service businesses around the world to help them improve and sustain cash flow generation and profitability together by focusing on flow. Read Part 1 of this series on Cash Flow Generation is a Priority.

Focus on Cash Flow Generation Like Never Before

In these uncertain times that we find ourselves in, cash flow is the one business factor that most companies around the world are focusing on. Yes, cash flow has always been carefully managed within businesses, but never more so than today. In many of the companies that we have worked with, profit levels have become a secondary issue in the short-term.

Many businesses that are now coming out of lockdown are simply just trying to scrape enough cash together to keep their operations going. Even those businesses that were cash-rich are seeing their reserves dry up. To help pull cash into the business so that financial obligations can be met, the speed of converting inbound materials into product is going to be vitally important.

Rapid Cash Flow Generation Through Lead Time Reduction

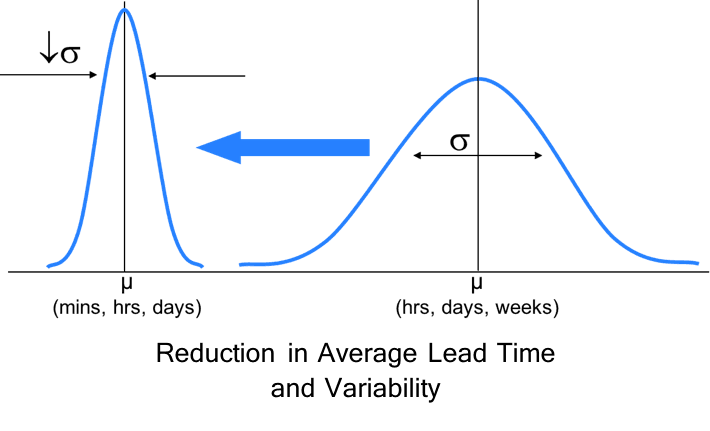

In this COVID-19 New Normal, the speed of cash flow generation is going to be a key factor for the immediate future. The ability to rapidly convert materials into shipped products as quickly as possible is and will be fundamental for the ongoing health of a business. More than ever before, manufacturing companies need to slash their lead times. Significant reductions in lead time will enable manufacturers to invoice earlier and to start the Accounts Receivable process, whatever the credit arrangements are. Additionally, lead time reductions that outstrip those of a company’s competitor will enable a business to maintain, and even gain market share whether COVID-19 is prevalent or not.

Manufacturing teams around the world need to seriously focus on lead time reduction to minimize the amount of time it takes from receipt of a customer order to receipt of the cash payment from the customer. By slashing manufacturing lead times from months, weeks and days to weeks, days and hours will help a company to survive into the future. Furthermore, lead time reduction is not limited to manufacturing environments. Additional lead time reduction can be found through creating flow within the shipping and administration functions to receive, ship and invoice orders. By significantly reducing lead times within the manufacturing and associated operations, a business will be able to maximize cash flow generation through the compression of the overall turnaround time from customer order to cash receipt.

Traditional point solutions such as Lean, focus on waste elimination and they are generally quite successful. However, as they focus on waste elimination within a localized area within a facility, we end up creating isolated islands of excellence, or as we call it Random Acts of Lean.

Point Solutions

A focused solution to quickly resolve issues and align processes for constraining or problematic manufacturing, supply chain or procurement processes that require an immediate and significant transformation

The benefits achieved in traditional Lean projects will more often than not be absorbed through downstream inefficiencies within the manufacturing facility. The upshot is that the customer doesn’t see any lead time benefit as overall lead times are not reduced. This often leads to financial and CFO frustration with no impact on the company’s financials.

Another general failure we see is that facility-wide Lean improvement projects look to create perfection, in the pursuit of excellence, improving area by area with small incremental improvements. In this COVID New Normal, and out of it for that matter, companies simply do not have the time to wait. What companies need is step-change, or a “big bang”.

High Impact’s comprehensive approach mitigates these frustrations and delivers tangible results quickly, generally within a couple of months.

To prioritize cash flow generation, we would utilize the tools and techniques of Demand Flow Technology that will enable us to slash lead times by up to 98%. This significant lead time reduction is achieved without changing the fundamental tasks required to make a product. Our tools focus on the creation of flow, connecting processes together and the development of a streamlined mixed model product flow through the entire facility.

The Business Improvement Strategy That Delivers Financial Improvement

In this post-COVID New Normal, industrial operational guidelines will keep staff safe and healthy and must be respected. However, they plainly work against traditional objectives of operational teams to continually look to improve productivity. As they come out of lockdown, many companies may well be seeing their lead times have now increased due to the COVID secure guidelines they have to follow. Slashing lead times becomes even more important for survival.

Demand Flow Technology provides the toolset to design and connect optimized flow through a manufacturing facility, or indeed any environment no matter the constraints on that environment. We can create a complete flow through a manufacturing environment synchronizing and balancing each process step to the demand requirements of the business.

As manufacturing lead times are slashed, so too are Work-In-Process inventories. In fact, one of our customers, a manufacturer of capital equipment, saw a 50% ($1 million) WIP reduction through focusing on lead time reduction and the creation of flow. As we require less inventory to support a Demand Driven environment, in the Old or in the COVID New Normal, those Make-To-Stock companies will also see a reduction in Finished Goods.

Working Capital is systematically converted into free cash flow as our customers see a step-change reduction in lead times and flow is created throughout their entire facility.

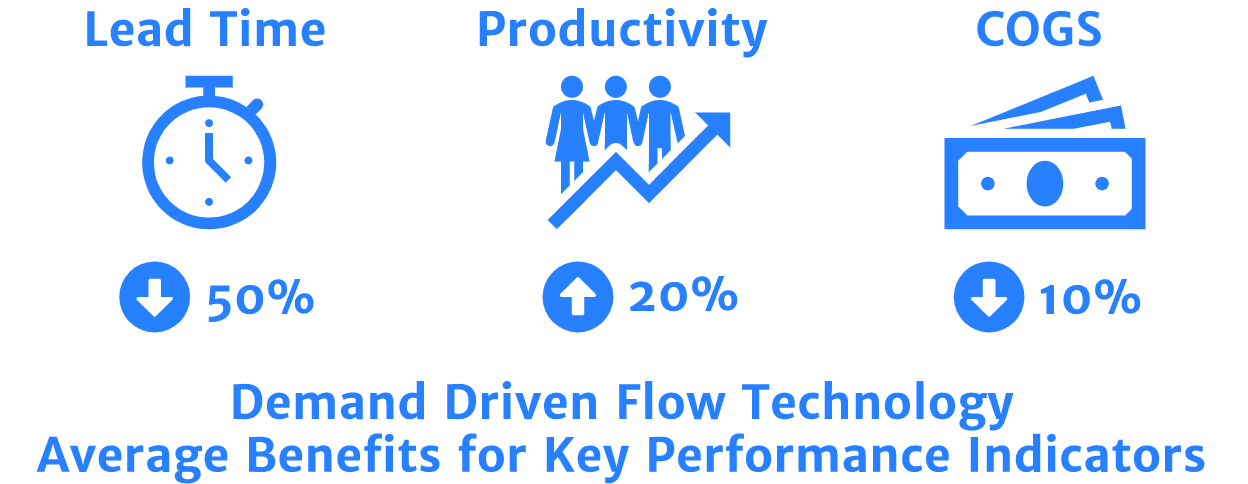

The benefits of implementing Demand Flow Technology are not limited to lead time reduction and inventory alone. Even in the COVID New Normal, productivity, capacity and space can all be improved. Cash flow and bottom-line results will be improved and sustained to enable a business to emerge from this COVID crisis much stronger and fitter than before, with the knowledge and tools to allow on-going improvements.

We enable companies to reduce lead times by as much as 98%, improve productivity by as much as 69% generating over 12% COGS improvement. Our implementations will also reduce WIP by as much as 60% while increasing levels of capacity and manufacturing in less space.

When a business significantly reduces lead time, improves productivity, customer service and COGS, the only options a competitor has is to take on more finished goods inventory, run overtime, hire more people and increase capacity which they then fill with Work-In-Process. The result is that the competitor continues to consume more and more cash, while your business takes advantage of the situation.

Our Demand Driven transformational manufacturing solutions are focused on creating synchronized and balanced flow through factories that generate sustainable bottom-line benefits. Leveraging these benefits helps our customers around the world to create competitive advantages in their marketplace.

Demand Driven Manufacturing Solutions

We provide our customers around the world with Demand Driven transformational manufacturing solutions that are focused to create synchronized and balanced flow through factories. Our business strategy dramatically compresses lead times, reduces inventory, improves productivity, increases capacity with no additional resources improving Cost of Goods Sold. Our customers achieve sustainable operational capabilities developing Demand Driven solutions that create a competitive advantage in their marketplace. All in all, we are able to generate sustainable bottom-line benefits.

We hear from C-Level executives all of the time that business improvement projects fail to deliver bottom-line benefits for the business. Our array of business improvement solutions solve this problem. We help our clients to leverage the skills of their organization along with our knowledge and expertize of Demand Driven manufacture and supply chain methodologies to deliver rapid and sustainable benefits.

For further information or to inquire how you can implement Demand Flow Technology, please email us at info@highimpactcs.com or send a message via our contact page.

Manufacturing & Supply Chain Information

Previous High Impact Insights:

- What is Demand Flow Technology

- What Is The Difference Between Lean and Demand Flow Technology?

- The Tools of Demand Flow Technology

- How Demand Flow Technology Impacts The Health of Your Business (1st of 3 Parts)

- Review of a Recent Demand Flow Technology Implementation

- The Supply Chain Methodology That is DDMRP

- What is DDMRP?

- MRP – Solution or Problem

- A Solution to Excess Inventories, Stocks-Outs & Poor Customer Service?

- Adapt or Die – Become Demand Driven

- Supply Chain Brain: DDMRP as an Emerging Disruptive Supply Chain Capability

- What Does VUCA Mean?

Overview of High Impacts’ Demand Driven strategies that will transform your factories and supply chain network:

LinkedIn Information:

Talk to us today to learn more about how we can help your organization become Demand Driven through the adoption of our Demand Driven methodologies, DDMRP and Demand Flow Technology.

Newsletter Sign-Up

Keep up-to-date on with what’s happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!