The term VUCA means Volatile, Uncertain, Complex and Ambiguous. VUCA was first sued by the United States Army War College when they discussed the conditions resulting from the Cold War. The VUCA concept has since been adopted throughout the businesses world, across many industry sectors. In particular, VUCA is gaining significant traction, especially with supply chain professionals so we have to ask why.

Firstly, let’s clarify what Volatile, Uncertain, Complex and Ambiguous (VUCA) means:

![]()

Volatility:

The change of speed within an eco-system such as in industry, a market or even the world. It relates to how much change takes place over what period of time. In business, we can see demand being subject to fluctuations over a very short period of time. The more volatile the environment is, the faster that change is taking place.

Uncertainty:

The compound of the situation where the events and outcomes are unpredictable. Uncertainty relates directly to the extent to which we can confidently predict (forecast) the future. So the more uncertain a business environment is, the harder it becomes to create any level of confidence in the forecast.

Complexity:

As the term suggests, complexity relates to the abundance of factors that need to be accounted for. The more factors and issues there are the more interconnections there are between the factors and therefore the more complex the environment becomes. The greater the complexity, the harder it is to analyze the environment.

Ambiguity:

This simply refers to the lack of clarity and therefore the difficulty to understand the situation or environment. The more ambiguous the environment is the harder it is to interpret

VUCA World

These four terms are related; the more complex and volatile a supply chain is, the harder it will be to predict and the more uncertain it will be.

Company systems and processes need to enhance performance and the ability of a company. In a VUCA world, supply chain operating systems need to deliver the highest level of adaptability, agility and must be fully aligned to the needs of the market to enable a company’s performance to be enhanced. This VUCA world is challenging the supply chain operating models of companies around the world. Today, organizations around the world are having to contend with challenging business environment where their supply chains have become more complex, elongated and fragmented, forecasts have gotten worse, customer tolerance times are becoming shorter and shorter and inventory optimization has become a major priority.

Over the years many companies have turned to Demand Driven Flow Technology (DDFT) as a way to enable their manufacturing operations to become responsive and agile enough to work within a VUCA environment. These Demand Driven manufacturing operations to become so agile and responsive that lead times reduce by 50% on average allowing these organizations to be able to react and adapt to the needs of the market increasing customer service. Has inventory optimization and cash flow become more important, organizations around the world are focusing on creating Demand Driven supply chains.

In our experience, many companies might think they are demand driven, however, when we look into their operations and systems we find that their supply chain management process is based on methodologies from the ’70s that are fully reliant on high levels of forecast accuracy. Demand Driven MRP is the evolving methodology that enables supply chain operating systems need to deliver the highest level of adaptability, agility that is fully aligned to the needs of the market to enable a company’s performance to be enhanced.

Traditional systems rely heavily on the forecast, which is either “lucky or lousy”. To maintain high levels of customer service within highly complex and elongated supply chains, some companies look to highly complex and expensive software applications to improve the forecast. There may be a marginal improvement in the forecast, but the likelihood is that the project will fail to increase the forecast enough for the company to be agile, responsive enough to function in their world of VUCA.

The alternative option is to move away from the focus on the forecast and to become truly Demand Driven utilizing the modern supply chain methodology, Demand Driven MRP (DDMRP).

Demand Driven MRP

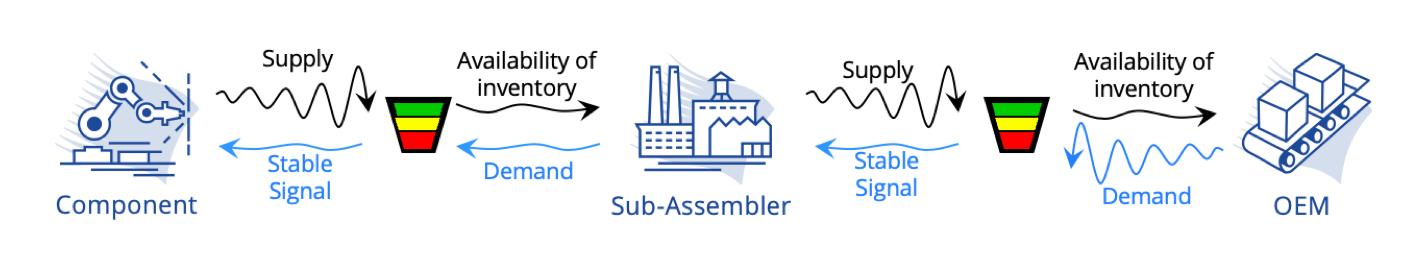

DDMRP provides the capability for Demand Driven planning, scheduling, and execution of the entire supply chain network; from end-users and distribution to manufacturing and multi-tiered suppliers. It is a Multi-Echelon Material and Inventory Planning and Execution system that dynamically sizes and adapts supply networks and production systems through sensing changes in actual demand patterns and supply responsiveness. Inventory is seen as strategic and decouples the entire supply network to absorb inherent supply chain variabilities and demand volatility enabling visibility, control, responsiveness, and agility.

DDMRP offers effortless management of your supply chain enabling visibility and control, lead time compression, reduction in inventory levels, improvement of customer satisfaction and a Return on Investment on working capital.

Most people think that to overcome the issues that exist in a VUCA world requires a complex and expensive software system. However, DDMRP has proven time and time again to work successfully in a VUCA world. The surprising thing is that the Demand Driven MRP methodology is simple to understand and TheONE is a low-cost cloud-based application that is responsive to their market while dramatically reducing lead time, eliminating variability and volatility across the entire supply chain and achieving Return on Capital Employed.

For information about supply chain optimization using DDMRP and how it will reduce your business risk read the following:

❯ Introduction to Demand Driven MRP (DDMRP)

❯ Supply Chain Professionals Are Migrating to The Cloud

❯ DDMRP Helps to Mitigate Business Risk

❯ Adapt or Die – Become Demand Driven

❯ DDMRP Is Not Another Way to Define Safety Stock?

Contact us today so that your company can start to reduce risk before your competitor does!

Newsletter Sign-Up

Keep up-to-date on what’s happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!

Email

info@highimpactcs.com

Address

High Impact House,

Ashby de la Zouch,

Leicestershire

LE65 1SP. UK

Telephone

US (Toll Free): +1 888 841 8621

UK Telephone: +44 7832 270 381