What is Supply Chain Management? This is a question that has been asked by many people in recent times. During the current COVID-19 Pandemic the use of the terms Supply Chain and Supply Chain Management have significantly increased. In particular, the use of these terms has been heavily used in media reports around the world regarding food shortages, personal protective equipment (PPE), and the various vaccine delivery programs.

The Supply Chain

Many companies view their supply chain as the flow of goods from their supplier into their factory. The supply chain encompasses the flow of goods and information between business entities.

Other companies will establish a definition that discusses a network created from points of consumption and supply, or Nodes, within their overall supply chain network. The nodes will define manufacturing facilities, distribution centers (centralized/regional and local hubs), suppliers, and customers. When each of these nodes is mapped to another an overall supply chain network is created.

At High Impact, we would view the supply chain as being from a supplier’s supplier all the way downstream through the factory to your customer’s customer. This integration of suppliers and customers to the manufacturing company is also not linear, in fact, it is more of a network of connecting nodes.

Supply Chain Management

A supply chain is not something that can be just set-up and left to operate on its own. It needs to be managed and evaluated regularly to ensure it is efficient in meeting the requirements of the business model. A successfully managed supply chain will provide any business a competitive advantage in their marketplace.

Supply chain management is a critical focus for companies that sell products and services. It is the function that connects and integrates the business functions and processes within the organization and across multiple companies into a cohesive model focused on the achievement of the business plan. Supply chain management includes all sourcing, procurement, planning, and logistics management activities, as well as the manufacturing operations, and it drives coordination of processes and activities across the entire business entity.

When we look at our client’s supply chains, we look at all the flows and activities that occur between the supplier’s supplier through to the customer’s customer. Within this flow, we identify all the people, processes, technologies, and information required to supply the product or service. The management of this supply chain is the integration of all the processes and business functions as well as the external integration with companies (suppliers and customers) required to align supply to actual demand, obtaining the required raw materials, converting these raw materials, based on appropriate quality levels, into a product, shipping that product to the customer efficiently and profitably striving for each element of the supply chain to be best in class.

The following descriptions of what supply chain management comes from the Association for Supply Chain Management (ASCM) and the Council of Supply Chain Management Professionals (CSCMP).

ASCM

The design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure leveraging worldwide logistics synchronizing supply with demand, and measuring performance globally.

CSCMP

Supply chain management encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers, and customers.

There are many definitions for supply chain management with each one having valid and pertinent points. What is important is creating a definition that fits your industry, your company, and your business model. There is no point trying to force-fit a definition just because one of many experts says that their definition is the true definition of supply chain management.

Every supply chain management decision you make will impact the experience of your customers and affect how much it will cost you to meet the needs of your customers. Make business decisions that generate a profit while giving your customer something they value. The key is first to understand who your customers are and what they value from your business. Then develop the supply chain model that fits with your business rules, meets the needs of your customers while making you a profit. If your marketplace needs products right away, then the entire supply chain from suppliers through manufacturing to logistics needs to be designed to enable the responsive supply of your products at a profit.

Demand Driven Supply Chain

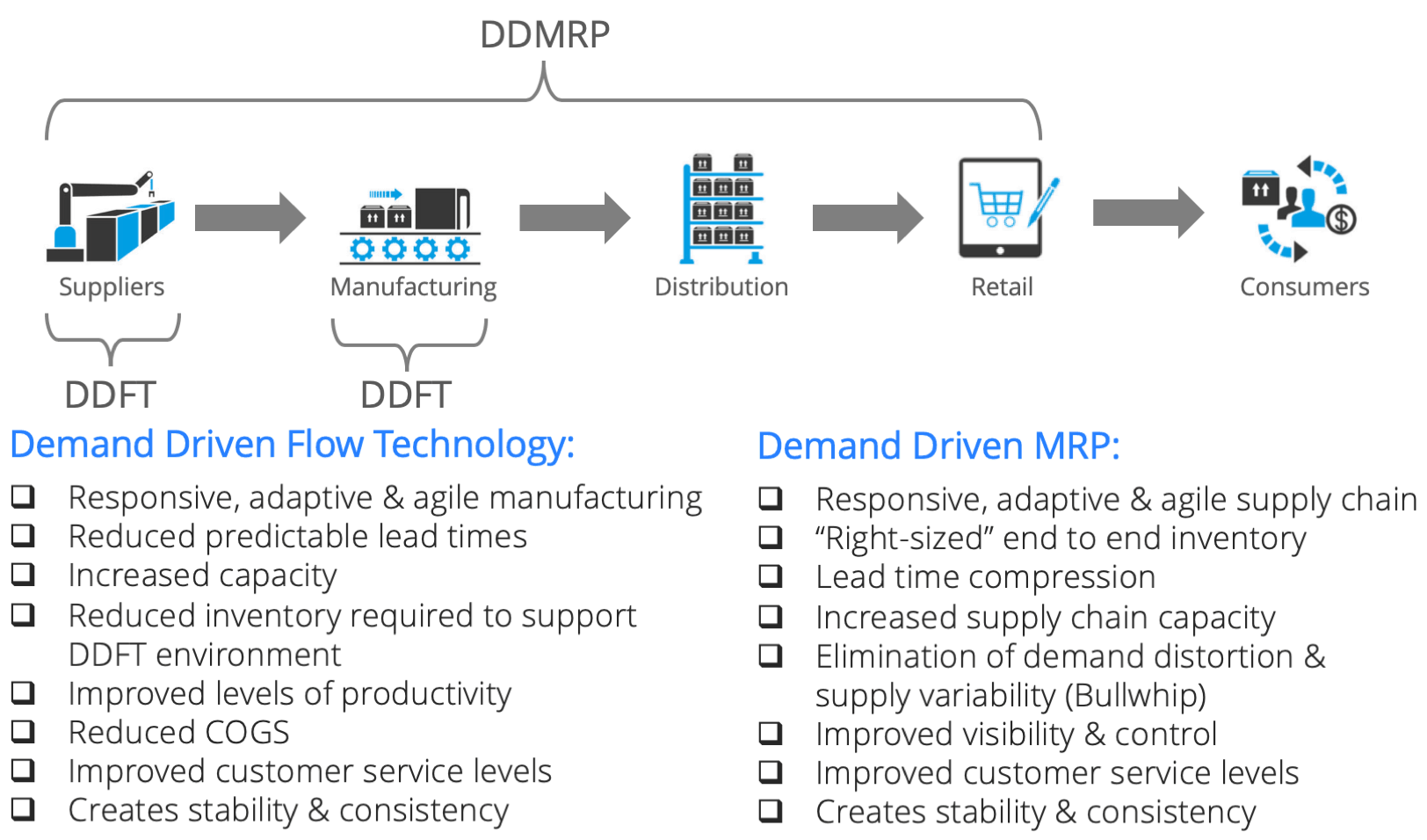

Some companies go down the route of stocking huge amounts of inventory only to find they stocked the wrong inventory. Some will create excess capacity with the manufacturing plant so they can ramp up quickly as demand ramps up but machines sit idle. The design of the supply chain needs to be Demand Driven and based on the business model and rules, to enable the reduction/elimination of excess inventory costs, and the positioning of optimum resource capacity. A Demand Driven supply chain model will give you just that where we integrate our Demand Driven solutions of Demand Driven Flow Technology (DDFT) with Demand Driven MRP (DDMRP).

A Demand Driven Supply Chain from High Impact Coaching & Strategies will enable responsive, agile manufacturing, and end to end supply chain optimization that will reduce your costs, inventory and lead times transforming your business into a world-class Demand Driven organization at the forefront of your industry.

Demand Driven Supply Chain Management Solutions

We provide our customers around the world with solutions that create synchronization and balance through the entire supply chain creating a competitive advantage in their marketplace. Demand Driven supply chains drive operational capabilities generating sustainable bottom-line benefits.

In the factory, Demand Driven Flow Technology focuses on the design and operation of the manufacturing flow. It is a comprehensive mathematical-based methodology that balances resource capability to actual, or planned demand, enabling a company to improve response capability to customer orders, reducing lead time, working capital, and Cost of Goods while improving productivity and overall customer satisfaction. DDFT is the framework that enabling manufacturing to be adaptive to daily changes in the required mix and actual demand.

Demand Driven MRP is the planning engine that drives the supply chain and the factory. It focuses on the optimization of strategically positioned inventory along the supply chain that absorbs demand volatility and supply variation we see in the bullwhip creating stability in supply downstream and demand creation upstream. Mathematical buffer designs that dynamically optimize inventory levels based on current market conditions and will reduce overall inventory across the entire supply chain while improving customer service levels and response capability. DDMRP provides the Supply Chain Planning and Execution tools to enable a company to become Demand Driven so that it can meet the expectations of its customers in today’s complex and volatile marketplace.

DDFT and DDMRP work together using actual demand to drive the Demand Driven supply chain removing traditional reliance on forecasting to drive the supply chain. The Demand Driven Supply Chain management activities still use the forecast, but now as an input for the Demand Driven Sales & Operations Planning (DDS&OP) process. DDS&OP will adapt the supply chain model based on the various business conditions and the forecast appropriately resizing the inventory buffers. Supply orders are now generated based on actual consumption from the dynamic buffers rather than based on a forecast requirement.

For further information or to inquire how you can implement Demand Driven Supply Chains please email us at info@highimpactcs.com or send a message via our contact page.

Manufacturing & Supply Chain Information

Previous Insights from High Impact Coaching & Strategies:

- What is Demand Driven Flow Technology

- What Is The Difference Between Lean and Demand Driven Flow Technology?

- The Tools of Demand Driven Flow Technology

- How Demand Driven Flow Technology Impacts The Health of Your Business (1st of 3 Parts)

- Review of a Recent Demand Driven Flow Technology Implementation

- Supply Chain Planning & Engineering

- The Supply Chain Methodology That is DDMRP

- What is DDMRP?

- MRP – Solution or Problem

- A Solution to Excess Inventories, Stocks-Outs & Poor Customer Service?

- Adapt or Die – Become Demand Driven

- Supply Chain Brain: DDMRP as an Emerging Disruptive Supply Chain Capability

- What Does VUCA Mean?

Overview of High Impacts’ Demand Driven strategies that will transform your factories and supply chain network:

LinkedIn Information:

LinkedIn Information:

Talk to us today to learn more about how we can help your organization become Demand Driven through the adoption of our Demand Driven methodologies, DDMRP and Demand Driven Flow Technology.

Newsletter Sign-Up

Keep up-to-date on with what’s happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!