Sales and Operations Planning (S&OP) is a powerful tactical business planning approach that aligns the demand and supply sides of a business while managing financial and operational objectives. Its whole purpose is to create a balance between demand and supply, ensuring that resources are optimized, inventory costs are minimized, customer service is enhanced, and revenue growth is achieved. S&OP holds a vital role in driving organizational success.

In this first of two articles, we will explore the fundamental aspects of S&OP, providing a clear understanding of each stage of the process. We will also highlight the benefits that can be gained from adopting S&OP as a business tactical process. In the second part, we will examine potential pitfalls that organizations may encounter during implementation and then finally, we will wrap up with a compelling conclusion that emphasizes the significance of S&OP and its potential impact on the prosperity of businesses.

Defining Sales and Operations Planning

S&OP, also known as Sales and Operations Planning, is a tactical process that focuses on aligning the demand and supply elements within an organization. It fosters collaboration and coordination among different departments like sales, marketing, finance, operations, and senior executive management.

The central objective of S&OP is to develop a unified and well-coordinated plan that effectively balances the organization’s financial objectives and operational capacities with the ever-changing customer demand. By considering crucial factors such as demand forecasts, production capacity, inventory levels, and resource availability, S&OP empowers businesses to make well-informed decisions that optimize their overall performance and drive success.

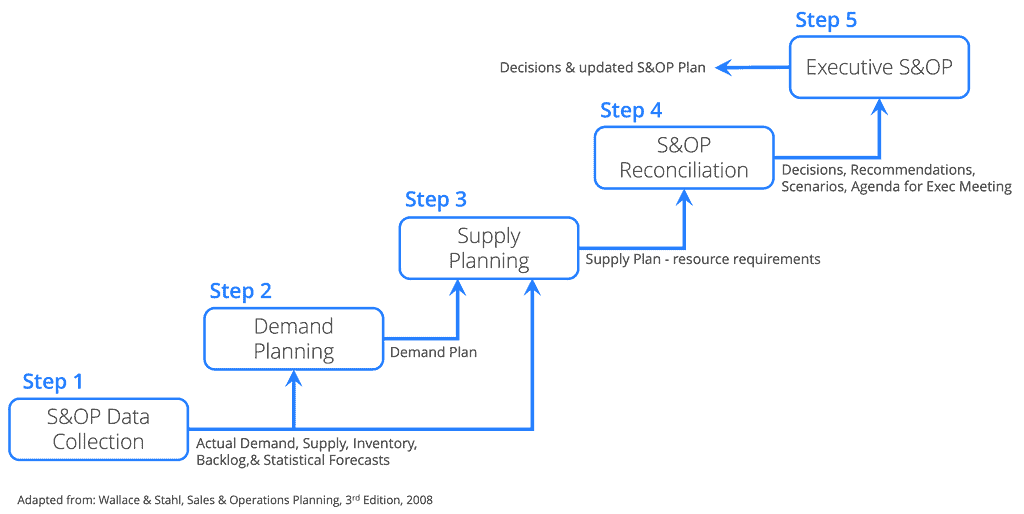

S&OP is not a one-time event or an improvement project but rather an ongoing cycle that typically follows a defined timeline, usually monthly. It involves a series of stages, including data gathering, demand, and supply planning, consensus building, and completing with an executive review and approval. The process requires continuous monitoring and periodic adjustments to respond effectively to market dynamics, changing customer needs, and internal factors impacting the business.

Ultimately, S&OP aims to improve the organization’s ability to meet customer demand, enhance operational efficiency, optimize inventory levels, minimize costs, and achieve financial targets. It serves as a vital tool for tactical and strategic decision-making, enabling businesses to align their resources and activities to achieve a competitive advantage in the marketplace.

Overview of the 5 Stages of S&OP

Step 1 – Data Collection

Gathering data serves as a critical foundation in supplying precise and trustworthy information to guide decision-making throughout the entire process. This entails collecting data from diverse sources, including historical sales, present orders, market trends, and competitive intelligence. Validating the data for accuracy, consistency, and reliability is crucial to guarantee the effectiveness of the process.

Step 2 – Demand Planning

The demand planning stage focuses on forecasting future demand for each product family or service. This involves considering various factors, including customer behavior, seasonality, promotional plans, new product launches, and market dynamics. To create a realistic and objective demand forecast, it is crucial to incorporate unbiased insights and industry knowledge, reflecting the true market potential.

Step 3 – Supply planning

In the supply planning stage, the focus is on establishing supply plans that are aligned with the demand plan requirements. This involves considering factors such as production capacity, inventory levels, supplier availability, and distribution network capabilities. The supply plan should be feasible, cost-effective, and responsive to meet the forecasted demand. It is essential to ensure a robust alignment between demand and supply to optimize resource utilization and minimize operational inefficiencies.

Step 4 S&OP Reconciliation (or Pre-S&OP)

S&OP Reconciliation, often referred to as Pre-S&OP, serves as a critical checkpoint where demand and supply plans are reconciled, and any gaps or issues are addressed. This stage involves a collaborative meeting that includes functional leaders and representatives responsible for plan execution. The Reconciliation meeting should result in a consensus on the best possible plan that aligns demand, supply, and financial objectives. The outcome of this meeting should be a well-balanced and integrated plan that optimizes business performance.

Step 5 – Executive S&OP

This final step involves presenting the integrated plan to the executive management team gaining their support and seeking approval of both the demand and supply plans. This meeting would include key decision-makers who possess the authority and accountability for the organization’s performance. The purpose is to secure commitment to the final plan that guides action plans for each function. This stage is crucial for driving alignment, securing necessary resources, and ensuring organizational-wide commitment to the S&OP process.

In part 2, we continue to discuss reshoring and its recent rise in popularity along with the factors and events driving executive decisions today.

In the second part of this introduction to Sales and Operations Planning, we will examine potential pitfalls that organizations may encounter during implementation. Finally, we will wrap up with a clear and concise conclusion that emphasizes the significance of S&OP and its potential impact on the prosperity of businesses.

Demand Driven Supply Chain Solutions

Wherever you manufacture, High Impact Coaching & Strategies can help you to reduce your Cost of Goods Sold by up to 23%, increase productivity by up to 69%, reduce manufacturing lead times by up to 90%, and increase capacity by up to 66%. By ALIGNING manufacturing and the supply chain to customer demand, promoting AGILITY to meet customer demand volatility, and ADAPTING capability as change takes place, we deliver exceptional results for our clients worldwide.

We provide our customers around the world with solutions that create synchronization and balance through the entire supply chain creating a competitive advantage in their marketplace. Demand Driven supply chains drive operational capabilities generating sustainable bottom-line benefits.

In the factory, Demand Flow Technology focuses on the design and operation of the manufacturing flow. It is a comprehensive mathematical-based methodology that balances resource capability to actual, or planned demand, enabling a company to improve response capability to customer orders, reducing lead time, working capital, and Cost of Goods while improving productivity and overall customer satisfaction. DFT is the framework that enables manufacturing to be adaptive to daily changes in the required mix and actual demand.

Demand Driven supply chains focus on the optimization of strategically positioned inventory that absorbs demand volatility and supply variation we see in the bullwhip creating stability in supply downstream and demand creation upstream. Dynamic and statistically designed inventory levels based on current market conditions and will reduce overall inventory across the entire supply chain while improving customer service levels and response capability. By being able to quickly adapt to changes in customer preferences or market conditions, Demand Driven companies can improve their customer satisfaction and increase their market share.

For further information or to inquire how you can implement Demand Driven Supply Chains please email us at info@highimpactcs.com or send a message via our contact page.

Manufacturing & Supply Chain Information

Previous Insights from High Impact Coaching & Strategies:

- What is Demand Flow Technology

- What Is The Difference Between Lean and Demand Flow Technology?

- The Tools of Demand Flow Technology

- How Demand Flow Technology Impacts The Health of Your Business (1st of 3 Parts)

- Cash Flow Generation is a Priority (1st of 2 Parts)

- Review of a Recent Demand Flow Technology Implementation

- What is Supply Chain Management?

- Supply Chain Planning & Engineering

- The Supply Chain Methodology That is DDMRP

- What is DDMRP?

- MRP – Solution or Problem

- A Solution to Excess Inventories, Stocks-Outs & Poor Customer Service?

- Adapt or Die – Become Demand Driven

- Supply Chain Brain: DDMRP as an Emerging Disruptive Supply Chain Capability

- What Does VUCA Mean?

Overview of High Impacts’ Demand Driven strategies that will transform your factories and supply chain network:

LinkedIn Information:

Talk to us today to learn more about how we can help your organization become Demand Driven through the adoption of our Demand Driven methodologies, DDMRP and Demand Flow Technology.

Newsletter Sign-Up

Keep up-to-date on with what’s happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!