In 2020, for many companies around the world, their survival into 2021 is going to come down to their ability to generate cash flow regardless of the level of profit. In this 2-part series, we discuss how Demand Driven Flow Technology will help businesses to improve the rate of cash flow generation during and after this COVID-19 pandemic. Our specific tools and methodologies are applied to manufacturing and service businesses around the world to help them improve and sustain cash flow generation and profitability together by focusing on flow.

The “Original” New Normal

For years High Impact Coaching & Strategies has been talking about a “New Normal”. In this New Normal supply chains had become extremely complex and were exhibiting high levels of demand and supply volatility. Forecasts were inaccurate and becoming worse, customer tolerance times were decreasing, the number of parts with long lead times were increasing, and product lifecycles had become shorter. Quite simply these were the economic realities of doing business prior to the COVID-19 pandemic. This was the original New Normal that manufacturing and supply chain professionals around the world worked in each and every day.

Customer Tolerance Time

The amount of time that a customer is willing to accept before they order from an alternative supplier. This customer tolerance time would be the lead time from the point an order is placed to the point in time it is shipped.

The COVID New Normal

Since the first incidence of COVID-19 in China and its subsequent global spread, supply chains are now exhibiting significantly different characteristics. This is now being referred to as the COVID New Normal with the factors of what is now the old New Normal have only gotten worse. With different periods of lockdown around the world, companies have had to contend with weeks or months of delayed shipments, to then experience their own marketplace drying up. If companies had materials in stock and customer orders, many were being affected with staff shortages and subsequently not able to fulfil those orders. Sadly as we all know, the majority of companies around the world have suffered greatly, although a small number of companies have been lucky and they have seen their demand explode.

The fact is that companies all over the world are experiencing unprecedented levels of supply variability and demand volatility, beyond what was experienced in the old New Normal. Forecasts have truly been ripped up and thrown out the window.

During this extraordinary time we see ourselves in, governments around the world have been issuing safe working guidelines that must be put in place before industry can get back to work and the economy can attempt a jump start. In particular, these requirements include a need to implement social distancing by up to 2 metres (6 ½ feet) depending on the country. In some cases, this could even mean production lines having to be closed down as operationally they are not able to meet COVID secure guidelines.

The ability of companies to service their marketplace has now become significantly more complex and tougher. These operational issues in conjunction with those of the old New Normal will further amplify the bullwhip. Further demand volatility and supply variability within the supply chain will take place making it even tougher for manufacturing facilities to meet their customer requirements.

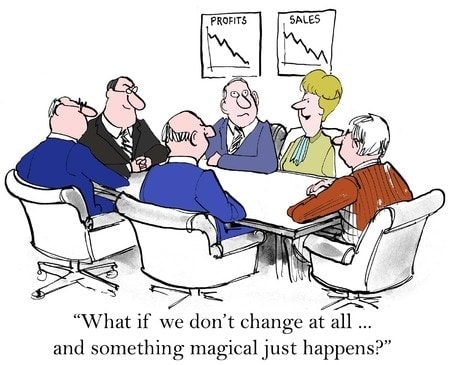

If a business is going to succeed, they must adapt to today’s COVID-19 New Normal otherwise they will no longer be able to exist. Adapting does not mean to accept and endure the constraints of this New Normal. Adapting is changing the way the business operates, the strategies, and maybe even the entire foundations of the business to enable survival and growth into the future. Failure to adapt and change could risk the future of the organization, as we discussed in a review of the 2016 Harvard Business Review. In this HBR article, the authors stated that there is a one in three chance that US Public Listed companies would be delisted by 2021, and this was written without any pandemic factors thrown into the mix. So add in COVID-19 and the levels of probability simply get worse.

Cash Flow Is Vital For Survival

This COVID-19 New Normal will most likely create further delays due to operational issues and/or disparity between supply and demand. This is turn will lead to further delayed/lost orders which in turn lead to reduced revenue. A vicious circle will develop throughout the entire global supply chain leading to loss of cash flow coming into businesses. Positive cash flow is going to be vital for survival.

To generate cash quicker, manufacturing companies need to slash their lead times. Companies must reduce the Order to Cash Cycle, more than ever before. Companies that will be the most successful at reducing the time it takes to convert materials into cash are going to be those that connect and synchronize all manufacturing/service functions, eliminate queuing and reduce the time it takes for a product to flow through the facility.

Read Part 2 of this series on “Cash Flow Generation is a Priority” to understand how High Impact Coaching & Strategies and Demand Driven Flow Technology can rapidly improve the cash flow of your business now and into the future. Furthermore, the tools and techniques we use will improve productivity, capacity, working capital and space creating sustainable bottom-line results to enable a business to emerge from this COVID crisis much stronger and fitter than before.

Manufacturing & Supply Chain Information

Previous High Impact Insights:

- What is Demand Driven Flow Technology

- What Is The Difference Between Lean and Demand Driven Flow Technology?

- The Tools of Demand Driven Flow Technology

- How Demand Driven Flow Technology Impacts The Health of Your Business (1st of 3 Parts)

- Review of a Recent Demand Driven Flow Technology Implementation

- The Supply Chain Methodology That is DDMRP

- What is DDMRP?

- MRP – Solution or Problem

- A Solution to Excess Inventories, Stocks-Outs & Poor Customer Service?

- Adapt or Die – Become Demand Driven

- Supply Chain Brain: DDMRP as an Emerging Disruptive Supply Chain Capability

- What Does VUCA Mean?

Overview of High Impacts’ Demand Driven strategies that will transform your factories and supply chain network:

LinkedIn Information:

Talk to us today to learn more about how we can help your organization become Demand Driven through the adoption of our Demand Driven methodologies, DDMRP and Demand Driven Flow Technology.

Newsletter Sign-Up

Keep up-to-date on with what’s happening in our Demand Driven World. Get information manufacturing and supply chain topics as well as news on client achievements, up and coming training events and other interesting stuff!